Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Delve into the vital role of inventory management in the food industry. Uncover how precise inventory control enhances freshness, minimizes waste, and ensures timely supply to meet dynamic consumer demands. Explore the key reasons why effective inventory management is a cornerstone for success in the ever-evolving food sector

Effective inventory management is paramount for the success and sustainability of the food industry. In a sector characterized by perishable goods, fluctuating demand, and stringent regulatory requirements, maintaining precise control over inventory is more than a necessity – it’s a strategic imperative. Accurate tracking and management of stock levels ensure that businesses can meet customer demand, minimize waste, and optimize costs. In an industry where freshness and quality are non-negotiable, streamlined inventory processes also contribute to enhanced food safety standards.

33% to 40% of the world’s food is lost or wasted every year, yet one in nine of the world’s population can’t get enough to eat—that’s equivalent to 800 million suffering from hunger.

This blog will delve into the multifaceted significance of inventory management within the food industry, exploring how it not only safeguards against potential losses but also fosters operational efficiency and customer satisfaction.

Inventory management involves the systematic control and supervision of a company’s goods, materials, and products. It includes processes such as ordering, storing, tracking, and managing stock levels to ensure efficient and cost-effective operations.

Inventory management is not just a logistical function in the food industry; it is a critical component that influences customer satisfaction, regulatory compliance, and the overall financial health of businesses operating in this dynamic and demanding sector.

In the food industry, inventory management holds significant importance. Efficient management helps prevent overstock or stockouts, ensuring that food products are consistently available for consumers. It aids in minimizing waste by optimizing stock levels, thereby reducing the risk of perishable items reaching their expiration dates before being sold. Effective inventory management in the food industry contributes to maintaining product quality, meeting customer demand, and enhancing overall operational efficiency.

In the realm of food businesses, instilling confidence and retaining consumers hinges on efficient inventory management—a pivotal factor for generating sales across various channels, be it online, in-store, or through kiosks. A robust inventory management system tracks supply stocks, streamlines labor-intensive tasks, aids in strategic storage planning for perishable items, and mitigates spoilage and waste. It acts as a safeguard against overselling, especially in the context of online sales and pre-orders, while also providing insights for informed supply ordering in the subsequent cycles.

Despite the vital role it plays, many food businesses still rely on manual inventory tracking across disparate software platforms, leading to inefficiencies and inaccuracies. Manual procedures lack real-time tracking capabilities and are prone to errors, posing challenges in adapting to changing consumer demands. In this era of constant change, businesses must be trend-responsive to meet evolving consumer expectations. To execute new inventory plans aligned with emerging trends, a responsive inventory management tool becomes indispensable.

For larger food businesses with warehouses, ensuring visibility of stock is a critical challenge. The ability to swiftly identify, locate, and requisition the right supplier item significantly impacts inventory operations and enhances the overall consumer experience. In the realm of managing perishable inventory, preventive measures such as proper care, storage, and inventory control are imperative. Setting minimum and maximum quantity limits in real-time helps mitigate issues like spoilage, food waste, and out-of-stock situations. Embracing a modern, trend-responsive inventory management tool is no longer a luxury but a strategic necessity for food businesses aiming to thrive in today’s dynamic market.

Explore the critical insights into the food industry’s greatest threat – product recalls.

Uncover the risks, challenges, and strategies to mitigate this menace in our blog.

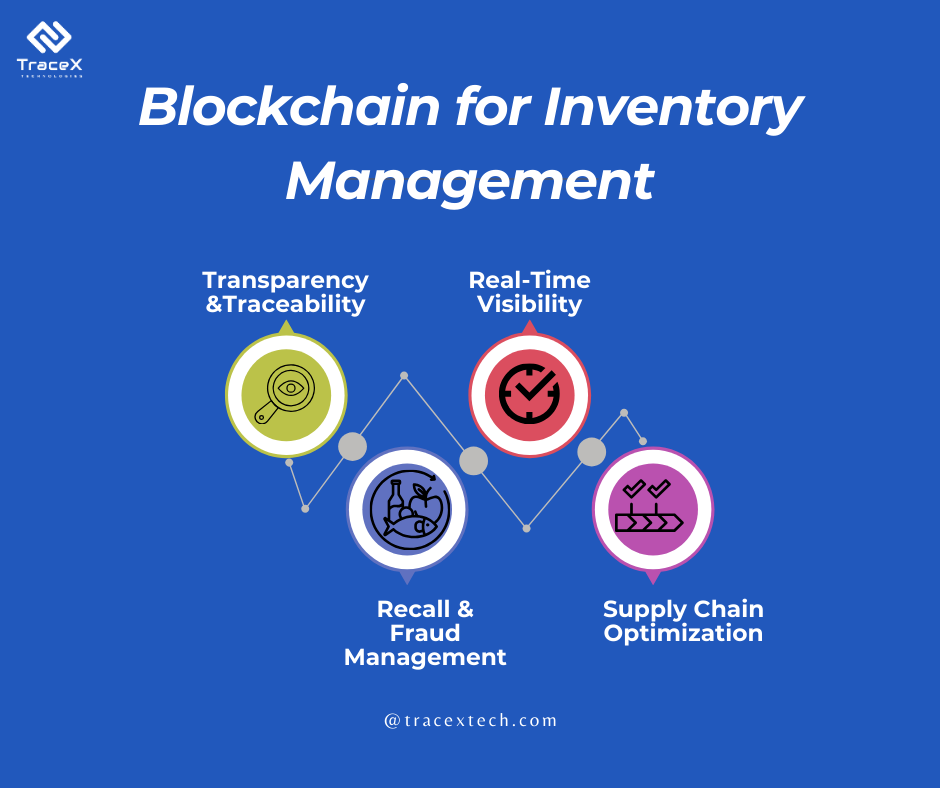

Blockchain offers a transformative solution to the challenges posed by fragmented supply chains and the need for optimized inventory management within the Consumer-Packaged Goods (CPG) industry. Designed to establish a seamless connection between every entity in the value chain – from suppliers and production sites to distribution centers and retail partners – Blockchain provides a comprehensive and immutable record of every transaction.

This transparency and permanency prove invaluable for manufacturers dealing with intricate aspects such as product origins, traceability, potential recalls, and managing perishable goods with limited shelf life. The key strength of a Blockchain solution lies in its ability to facilitate real-time, seamless data flow between all parties involved. This affords manufacturers instantaneous visibility into consumer-level demand, an unprecedented advantage in the past.

With this newfound insight, manufacturers can move beyond reactive measures to proactively plan for manufacturing and replenishment. This shift enables them to accurately forecast demand, ensuring that they always maintain optimal stock levels of the right products. Striking this balance allows for the optimization of revenue and profitability while mitigating the risks associated with lost sales and excessive carrying costs. Blockchain’s ability to enhance visibility, traceability, and demand forecasting represents a paradigm shift in inventory management, enabling CPG brands and manufacturers to thrive in the dynamic landscape of modern supply chains.

The use of RFID (Radio-Frequency Identification) and barcoding is a technological advancement in inventory management. RFID tags and barcodes provide unique identifiers for each product, facilitating accurate and efficient tracking throughout the supply chain. This technology minimizes errors, improves inventory accuracy, and enhances the speed of data collection, making it a valuable asset in modern inventory control systems.

Automation in inventory tracking involves the use of technologies like sensors and robotics to monitor and manage stock levels. Automated systems can conduct tasks such as order fulfillment, replenishment, and data analysis without human intervention, reducing the likelihood of errors and increasing the speed of operations. This not only improves accuracy but also frees up human resources for more strategic and value-added tasks within the inventory management process.

TraceX’s blockchain-powered traceability solutions revolutionize inventory management by introducing transparency, real-time visibility, and data integrity. By leveraging these features, businesses can mitigate risks, enhance operational efficiency, and adapt to the dynamic demands of the modern supply chain.

TraceX utilizes blockchain technology to create an immutable and transparent ledger of all transactions within the supply chain. This ensures a comprehensive traceability system from the origin of products to their final destination. Each transaction, including production, transportation, and distribution, is recorded on the blockchain, providing a permanent and unalterable record. This transparency is invaluable for inventory management, as it allows stakeholders to trace the journey of each product in real time.

The blockchain-powered system of TraceX enables real-time data updates and sharing across the supply chain. This instant visibility into inventory levels, movements, and transactions allows for more informed decision-making. Manufacturers, distributors, and retailers can access the most up-to-date information, helping them respond promptly to changes in demand, supply chain disruptions, and other factors affecting inventory.

In the event of a product recall, TraceX’s blockchain-powered traceability allows for swift and precise identification of affected batches. This facilitates targeted recalls, minimizing the impact on the entire inventory and reducing waste. Quick and accurate recall management is crucial for maintaining consumer safety and regulatory compliance.

The decentralized nature of blockchain ensures that once information is recorded, it cannot be altered or tampered with. This reduces the risk of errors, inaccuracies, or fraudulent activities in inventory data. The integrity of the data on the blockchain builds trust among supply chain partners, enhancing the overall reliability of inventory information.

With a clear view of the entire supply chain through TraceX, organizations can optimize their inventory levels, streamline production planning, and minimize stockouts or overstock situations. The data-driven insights provided by the traceability solution enable more accurate demand forecasting and inventory replenishment strategies

Unlock the secrets to seamless inventory management with TraceX Solutions!

Explore our blog to discover how blockchain-powered traceability enhances accuracy, transparency, and efficiency

FIFO (First-In-First-Out) and FEFO (First-Expired-First-Out) principles are essential inventory management methods. FIFO ensures that the oldest items in stock are used or sold first, minimizing the risk of product obsolescence and waste. FEFO takes this a step further by prioritizing items based on expiration dates, crucial for industries dealing with perishable goods. These principles promote inventory freshness, reduce holding costs, and contribute to overall inventory optimization.

Regular audits and cycle counts are vital for maintaining accurate inventory levels. Conducting routine checks helps identify discrepancies between recorded and actual stock levels, preventing errors that could lead to overstock or stockouts. This continuous monitoring ensures the reliability of inventory data, supporting informed decision-making and preventing operational disruptions.

Collaborative planning with suppliers is key to effective inventory management. By sharing demand forecasts, sales data, and production schedules with suppliers, businesses can enhance supply chain coordination. This collaborative approach minimizes lead times, reduces the risk of stockouts, and ensures a more efficient flow of goods. Open communication with suppliers supports a responsive and adaptable inventory management strategy that aligns with market demands.

Discover the success story of achieving complete traceability and a farm-to-fork narrative through our blockchain-powered inventory management solutions.

Embark on the journey of Svojas Farms with TraceX’s Trace-Pro!

In conclusion, effective inventory management is a linchpin for success in diverse industries, providing a strategic framework to navigate challenges and capitalize on opportunities. By embracing principles such as FIFO and FEFO, businesses can optimize stock usage, reduce waste, and enhance overall inventory efficiency. Regular audits and cycle counts act as vigilant guardians, ensuring that recorded inventory aligns with actual stock levels, preventing costly errors.

Integration of technology, including RFID, barcoding, and advanced software, propels inventory management into the digital age, offering real-time visibility and automation that streamline operations. These technological advancements not only improve accuracy but also empower businesses to make data-driven decisions for procurement, demand forecasting, and order fulfillment.

Moreover, collaborative planning with suppliers fosters a synchronized supply chain, reducing lead times and promoting a more responsive and adaptable inventory strategy. In essence, a well-executed inventory management strategy not only reduces costs and improves profit margins but also enhances customer satisfaction, operational efficiency, and overall competitiveness in the dynamic landscape of modern business.