Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Explore the intricate challenges within the grocery supply chain, from sourcing raw ingredients to delivering products to stores. Discover how industry players navigate complexities to ensure seamless operations and meet consumer demands effectively.

The grocery supply chain is more intricate than many people realize. From sourcing fresh produce to ensuring shelves are stocked in time for a weekend rush, each step is a balancing act. But here’s the catch—one small delay or miscommunication can cause a ripple effect, leading to stock shortages, spoilage, and even customer dissatisfaction.

According to Forbes, in the United States alone, there are approximately 2 million farms catering to over 60,000 grocery stores and nearly 750,000 restaurants nationwide

The grocery supply chain is a complex web that involves various stakeholders working together seamlessly to ensure products reach store shelves. From farmers and manufacturers to distributors and retailers, each plays a crucial role. A well-functioning supply chain is the backbone of the grocery industry. It not only ensures a steady flow of products but also impacts factors like inventory management, pricing, and ultimately, customer satisfaction.

Key Takeaways

The grocery supply chain encompasses the sourcing of raw ingredients, their processing and packaging, and their subsequent delivery to stores for sale. While fresh fruits and vegetables often undergo minimal processing and are transported directly from the farm to the store, perishable items require refrigeration during shipping. Packaged goods like crackers, breakfast cereals, and margarines follow a more intricate manufacturing process, where raw ingredients are sourced from suppliers, processed, combined, and cooked or baked, with different levels of automation. The finished products are then packaged and distributed to various buyers, warehouses, or directly to retail grocers.

At the forefront is the food and agricultural value chain with the agricultural producers, the farmers and ranchers who cultivate crops and raise livestock, providing the raw materials that fuel our food system. These producers then collaborate with processors and packagers, who transform these raw materials into consumer-ready products, from freshly squeezed orange juice to frozen dinners. Once packaged, the goods journey onwards to wholesalers and distributors, who act as intermediaries, purchasing products in bulk from producers and then selling them to retailers in smaller quantities. Finally, we have the retailers, the grocery stores we frequent, who stock their shelves and fulfill the needs of everyday consumers.

Fresh produce such as fruits, vegetables, dairy, and meats are highly perishable and require swift handling to maintain their freshness and quality. Cold chains, which are temperature-controlled supply chains, play a crucial role in preserving the freshness of these items during transportation. Refrigeration is utilized throughout the entire supply chain, from the moment the products are harvested or processed to their delivery to retailers or consumers.

One of the greatest challenges in the grocery supply chain is managing demand volatility. Consumer preferences are constantly shifting, influenced by factors such as changing dietary trends, seasonality, and even social media crazes. A sudden surge in demand for a particular product can quickly deplete inventory levels, leaving retailers scrambling to restock while maintaining customer satisfaction.

The perishable nature of many grocery items adds another layer of complexity to the supply chain. Fresh produce, dairy products, and meats have a limited shelf life, and managing their flow through the supply chain is a delicate dance. Retailers must carefully monitor expiration dates, rotate stock, and implement effective spoilage prevention strategies to minimize waste and ensure that customers receive the freshest possible products.

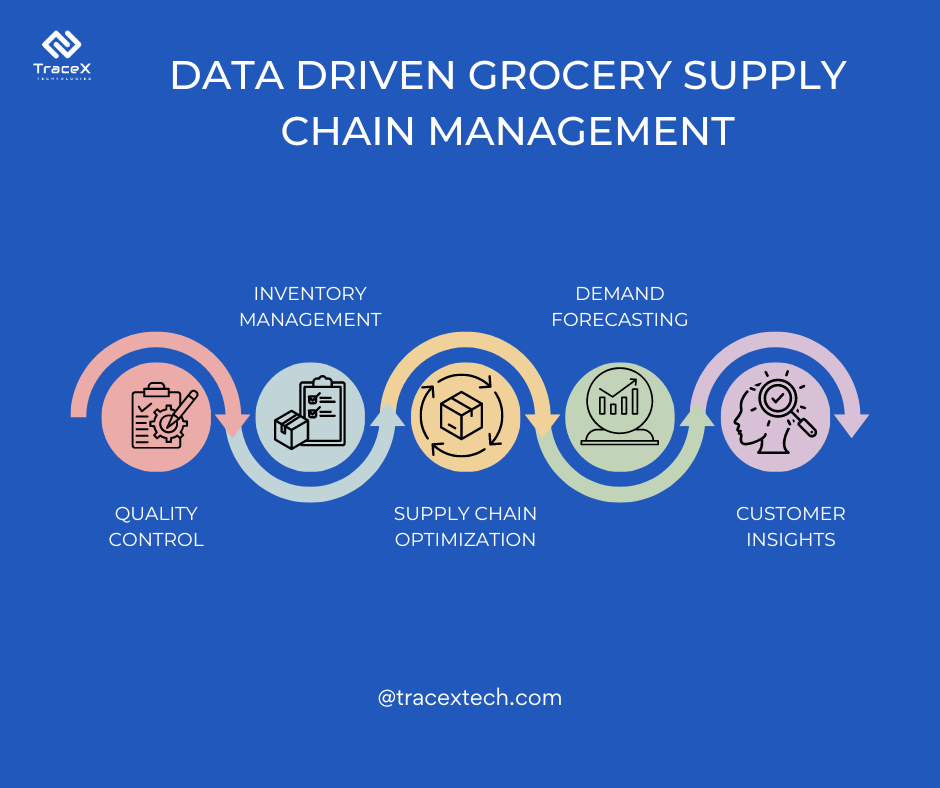

Effective inventory management is crucial in the grocery supply chain. Retailers must strike a careful balance between having enough stock to meet consumer demand while avoiding excess inventory that could lead to spoilage and waste. This involves sophisticated forecasting techniques, close collaboration with suppliers, and real-time monitoring of sales data to anticipate shifts in demand.

In recent years, sustainability has become a top priority for many stakeholders in the grocery supply chain. The environmental impact of food production, transportation, and waste is a growing concern, and companies are actively seeking ways to reduce their carbon footprint and promote more sustainable practices.

In the grocery supply chain, food supply chain management plays a crucial role in ensuring that products move efficiently from farm to shelf. It involves managing the entire process of sourcing, transportation, storage, and distribution of perishable goods such as fruits, vegetables, dairy, and meat, while maintaining quality and safety.

However, the complexity of food supply chains means that any disruption—whether it’s a delay in shipping or miscommunication between suppliers and retailers—can lead to wasted products, stockouts, and increased operational costs. With rising consumer expectations for fresh, high-quality items, effective supply chain management has become even more important for grocery stores to meet demand without compromising on quality or incurring significant losses.

By implementing advanced tracking and traceability solutions, grocery chains can streamline operations, optimize inventory management, reduce spoilage, and ensure that the food consumers receive is safe and fresh.

Traceability refers to the ability to track a product’s movement and history through every step of the supply chain, from its origin on the farm or in the factory to its final destination on the consumer’s plate.

The importance of traceability cannot be overstated. It provides a comprehensive view of a product’s journey, enabling stakeholders to identify and address potential issues swiftly, ensuring food safety, and promoting transparency and accountability throughout the supply chain.

One of the primary benefits of traceability is its role in enhancing food safety .By tracking products at every stage, it becomes possible to quickly identify the source of any contamination or quality issue. This information is invaluable in facilitating rapid recalls, minimizing the spread of foodborne illnesses, and protecting consumer health.

Moreover, traceability empowers consumers by providing them with detailed information about the products they purchase. With increasing awareness and demand for sustainable and ethically sourced food, consumers seek transparency regarding a product’s origins, production methods, and environmental impact. Traceability enables grocery retailers to offer this level of transparency, building trust and fostering stronger relationships with their customers.

Beyond food safety and consumer trust, traceability also plays a crucial role in supply chain efficiency and waste reduction. By tracking products throughout the supply chain, stakeholders can identify bottlenecks, optimize logistics, and minimize spoilage and waste, resulting in cost savings and a reduced environmental footprint.

As the grocery supply chain continues to evolve and adapt to changing consumer demands and global challenges, traceability will remain a critical cornerstone, ensuring the integrity, safety, and sustainability of the food we consume.

The sustainability aspect of the grocery supply chain involves minimizing environmental impact, conserving resources, and promoting ethical practices throughout the entire process from sourcing to consumption. This includes initiatives to reduce carbon emissions, optimize packaging to minimize waste, support sustainable farming practices, promote fair labor conditions, and prioritize the use of renewable energy sources. Sustainability efforts aim to ensure that the production, transportation, and distribution of food products are conducted in a manner that is environmentally responsible, socially equitable, and economically viable for both present and future generations.

One such initiative is the adoption of sustainable farming practices which aim to minimize the use of synthetic pesticides and fertilizers while promoting soil health and biodiversity. Additionally, efforts are being made to reduce food waste throughout the supply chain, from implementing better inventory management practices to donating surplus food to charitable organizations.

Transportation is another area where sustainability efforts are being made, with a focus on reducing emissions through the use of more efficient and eco-friendly modes of transportation, such as electric or hybrid vehicles.

Packaging is also a significant concern, with many companies exploring alternatives to traditional plastic packaging, such as biodegradable or compostable materials. Recycling programs and initiatives to reduce packaging waste are also gaining momentum throughout the supply chain.

TraceX Food Traceability platform brings transparency into the farm-to-fork journey of grocery products by leveraging blockchain technology to record and track every step of the supply chain. From the farm where the ingredients are grown to the manufacturing facilities, distribution centres, and retail stores, TraceX creates an immutable record of each transaction and movement. This transparency enables consumers and stakeholders to access detailed information about the origins of the products, the farming practices employed, transportation routes, processing methods, and more. By scanning a QR code or accessing an online platform, consumers can gain insights into the entire journey of the product, ensuring greater trust, accountability, and confidence in the food they purchase.

Go Desi, a popular snack brand, partnered with TraceX Technologies to implement QR code-based traceability for their products, starting with their flagship snack, Imli Popz. By leveraging TraceX’s blockchain-powered traceability solution, Go Desi enabled consumers to scan a QR code and access detailed information about the product’s ingredients, sourcing, and sustainability practices.

This innovative feature improved transparency, strengthened consumer trust, and positioned Go Desi as a leader in ethical sourcing and supply chain transparency. The brand plans to expand this feature to other products, driving engagement while ensuring compliance with sustainability standards.

As consumer demands and expectations continue to evolve, the grocery supply chain will need to adapt and innovate to stay ahead of the curve. Emerging technologies, such as blockchain, Internet of Things (IoT), and artificial intelligence (AI), are already being explored as potential solutions to address some of the challenges faced by the industry.

As the world’s population continues to grow, and consumer preferences evolve, the grocery supply chain will need to rise to the challenge, embracing innovation and adopting sustainable practices to meet the demands of the future. While the complexity of this intricate system can be daunting, the industry’s commitment to continuous improvement and adaptation is a testament to its resilience and importance in ensuring a reliable and secure food supply for all.

The grocery supply chain faces several challenges, including fluctuating consumer demand, inventory management, food safety regulations, and supply disruptions due to events like natural disasters or pandemics. Additionally, the need for transparency and traceability in sourcing, along with increasing pressure for sustainable practices, adds complexity to supply chain operations.

Supply chain disruptions can lead to shortages of specific products, which may cause prices to rise due to increased demand and limited supply. Factors such as transportation delays, labor shortages, and rising costs of raw materials can further exacerbate these issues, ultimately affecting pricing strategies and profit margins for grocery retailers.

Technology plays a crucial role in addressing grocery supply chain challenges by improving visibility and efficiency. Solutions like inventory management software, demand forecasting tools, and blockchain for traceability help streamline operations. Additionally, technologies such as IoT sensors and AI can enhance real-time tracking, monitor food safety, and optimize logistics, ultimately leading to a more resilient supply chain.