Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Batch traceability is crucial in spice manufacturing for quality control, compliance, and consumer trust. Unique Process Batch IDs enable tracking from farm to table, ensuring transparency and accountability. Technology integration streamlines operations and data management, enhancing quality control and recall management.

Traditional supply chains often lack visibility, making it difficult for consumers to understand the journey of their spices. Without transparent traceability, consumers struggle to trust the claims made by spice companies. Batch inconsistencies and potential contamination risks can be difficult to track and address without robust batch traceability systems. Batch Traceability in Manufacturing is critical in maintaining consistency and quality in the global spice market.

In the rapidly evolving food industry, maintaining quality and ensuring safety are paramount. For spice manufacturers, this involves a complex web of processes, from sourcing raw materials to delivering the final product. Traceability, the ability to track every step in the supply chain, is not just a regulatory requirement but also a competitive advantage.

The global spice industry is vast and complex, with spices traveling long distances from diverse origins to reach our kitchens. However, this complexity can create a vulnerability: a lack of transparency in the supply chain

The first step in implementing a traceability system was to identify key points in the manufacturing process where traceability would be most beneficial. These included:

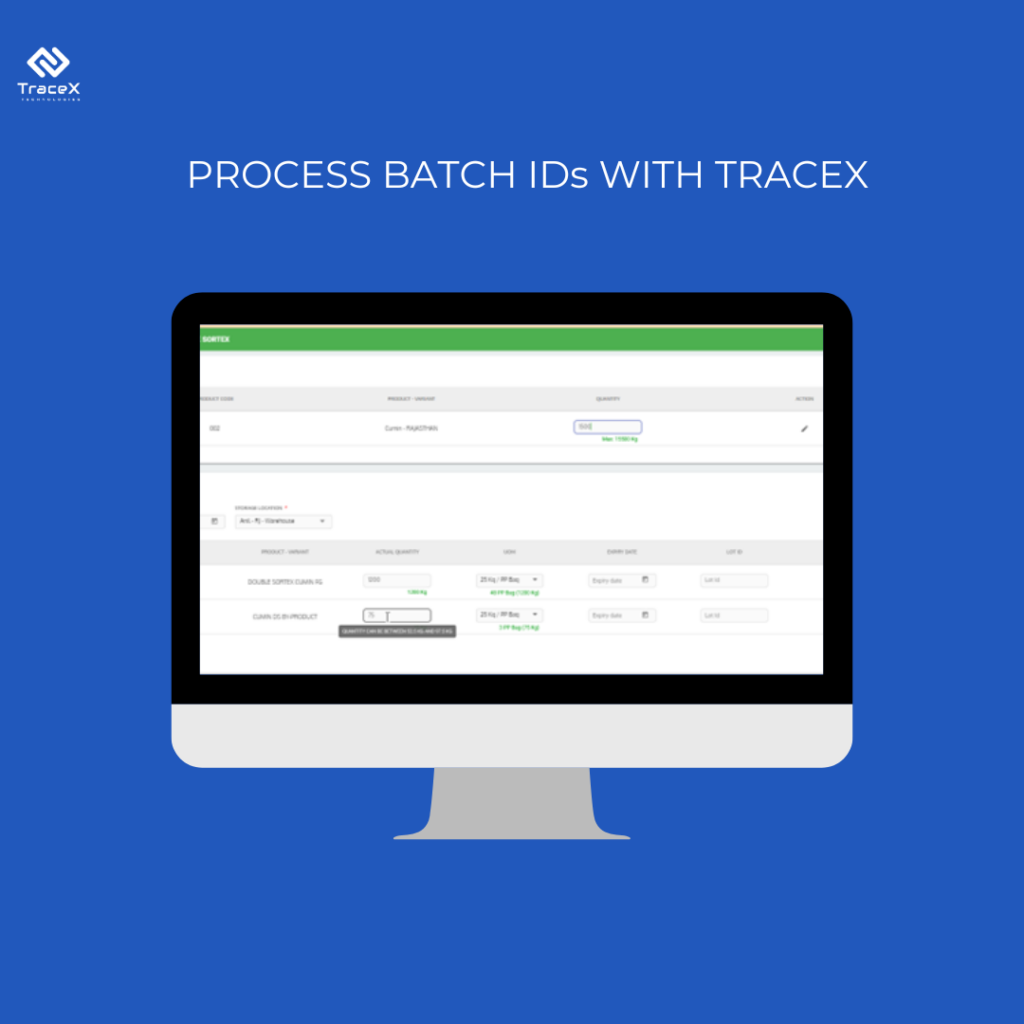

Each batch of raw materials and processed products was assigned a unique Process Batch ID. This ID acted as a digital fingerprint, linking every step in the production and supply chain. The batch ID encompassed:

– Supplier information

– Harvest date and location

– Quality inspection results

– Processing dates and methods

– Packaging details

– Distribution routes

The spice tech company integrated cutting-edge technology to facilitate traceability:

With the implementation of process batch IDs, the company could now track each batch’s quality parameters meticulously. Any deviations were quickly identified and addressed, ensuring that only the highest quality spices reached the market.

The traceability system provided comprehensive records required for compliance with various food safety regulations. This not only reduced the risk of regulatory penalties but also facilitated smoother audits and inspections.

By providing transparency into the journey of their products, the spice tech company gained consumer trust. Customers could scan a QR code on the packaging to see the entire journey of the spices from farm to table, enhancing brand loyalty.

In the rare event of a product recall, the company could quickly identify and isolate the affected batches using the process batch IDs. This minimized the impact of recalls, reducing financial losses and protecting the brand’s reputation.

The integration of technology streamlined various processes, from procurement to distribution. This increased operational efficiency, reduced waste, and optimized resource utilization.

This use case demonstrates how process batch IDs was implemented in the Davana oil production process, enhancing traceability and data management for the spice tech company.

Processing:

The scenario involves a single process with multiple steps:

1. Cleaning

2. Drying

3. Extraction

4. Filtration

Process Batch IDs:

Process Inputs and Outputs:

Inputs: The initial quantity of raw produce for each batch is recorded along with the assigned process batch ID.

Outputs: At each stage (dried herbs, crude oil), the quantity of material is recorded and linked to the corresponding process batch ID. This allows for tracking of yield and potential losses throughout the process.

Benefits of Process Batch IDs:

Implementation:

From Farm to Fork, with Full Transparency: See how a leading spice tech company uses TraceX to deliver authentic, sustainable spices.

The implementation of a traceability system with process batch IDs has transformed the operations of the spice tech company, ensuring high quality, regulatory compliance, and enhanced consumer trust. By leveraging technology and innovative practices, the company has set a new standard in the spice industry, demonstrating the profound impact of traceability on manufacturing processes. As the industry continues to evolve, such systems will become increasingly essential, driving efficiency, transparency, and sustainability.

By focusing on quality control, regulatory compliance, and consumer transparency, the spice tech company has not only improved its operational efficiency but also positioned itself as a leader in the industry. This case study serves as a valuable example for other companies looking to enhance their manufacturing processes through traceability and process batch IDs.