Contact: +91 99725 24322 |

Menu

Menu

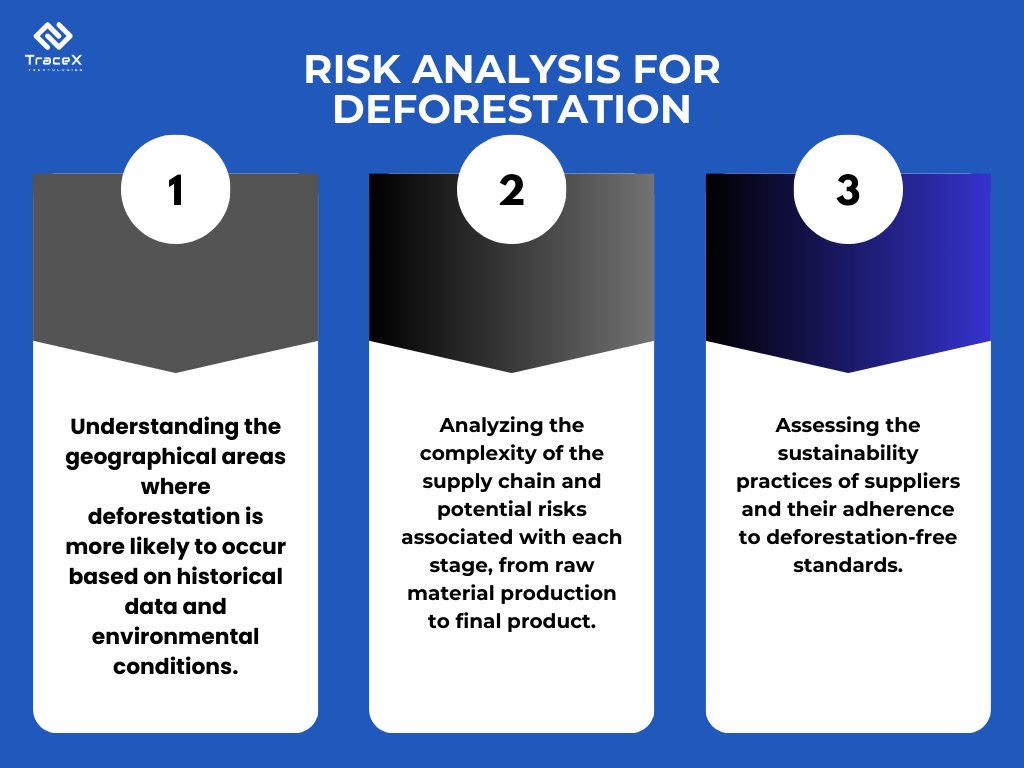

Quick summary: Explore the essential components of Compliance Risk Assessment for the EU Deforestation Regulation (EUDR). This blog delves into identifying, evaluating, and mitigating risks associated with deforestation in supply chains. Learn how to ensure regulatory compliance and implement effective risk management strategies to maintain sustainability and avoid penalties.

Whether you’re just getting started or trying to scale your process across thousands of batches and suppliers, understanding this is the critical first step toward staying compliant—and competitive—in the EU market. EUDR (EU Deforestation Regulation) compliance doesn’t just depend on where your goods come from—it depends on what evidence you can show. Without a system to assess, monitor, and mitigate risk, your Due Diligence Statement (DDS) could be rejected by EU authorities, halting shipments or damaging your credibility with buyers.

If you think sourcing from a “low-risk country” guarantees smooth EUDR compliance—you might be in for a surprise. The truth is, even products that appear compliant on the surface can fail EUDR risk assessments if they’re missing plot-level geolocation, proof of no deforestation, or batch-level documentation.

The challenge? Most businesses lack a clear, operational framework to evaluate compliance risk across global supply chains.

This guide is designed for:

Key Takeaways

What does “risk” mean under EUDR?

Under the EUDR system, risk refers to the likelihood that your product is linked to deforestation or was not produced in compliance with applicable laws—and whether you’ve taken reasonable steps to confirm otherwise. This applies whether you’re buying coffee from a certified co-op or rubber from a remote plantation.

Here’s the reality: Even if you believe your product is clean, lack of documentation, fuzzy geolocation, or unverified sourcing practices can flag your shipment as “high risk.” That’s what puts your Due Diligence Statement (DDS) at risk of rejection inside the EU’s TRACES system.

These aren’t just “nice-to-have” elements. Without them, you can’t submit a valid DDS—and if you do, it might not pass inspection.

“But what if I source from a low-risk country?”

Even if you’re importing from a “low-risk” country like the Netherlands or USA, you are still legally required to submit a DDS. The only difference is that fewer shipments (around 1%) will be checked by EU authorities.

If you’re randomly selected, and your documentation isn’t airtight, your product could be blocked from the market. So while the probability of inspection is lower, the penalty for non-compliance is just as high.

“What actually triggers an audit?”

In other words, audits aren’t just based on what you do—they’re also triggered by who you source from and how prepared you are to prove compliance.

If you’re an importer, exporter, or trader, your biggest risk isn’t the land itself—it’s not being able to show where your product came from and how it was produced. That’s the gap TraceX helps close.

With digital traceability, satellite-backed land verification, and batch-level compliance records, platforms like TraceX ensure you know your risk—and prove your compliance in real time.

Compliance under EUDR feels overwhelming. There’s data to collect, maps to verify, documents to audit, and suppliers to chase across time zones. But if you don’t get ahead of risk, it’ll get ahead of you—fast.

Whether you’re a compliance officer trying to keep shipments moving, a procurement lead managing hundreds of suppliers, or a sustainability head facing pressure to “get it done”, this is the roadmap you’ve been looking for.

Here’s exactly how to assess EUDR compliance risk—step by step, minus the guesswork.

You can’t assess risk without knowing where your raw materials come from. Start by collecting accurate, verifiable geolocation data—preferably polygons, not just single GPS points.

Why it matters: The EU wants proof that your product didn’t come from deforested land. If your coordinates are off—or missing—you’re non-compliant from the start.

Use mobile tools that allow offline geo-capture from the field. Platforms like TraceX let you upload, validate, and even tag farm boundaries in real time.

Next, check how the EU classifies the country you’re sourcing from—low, standard, or high risk. This determines your risk mitigation obligations.

But here’s the catch:

Even low-risk countries require full DDS submission. The only difference is how often you’re inspected.

Where can I check my country’s risk status?

Don’t take your supplier’s word for it. Review:

Why this matters: If your upstream supplier can’t prove they legally produced the commodity, your DDS is at risk—even if the plot is compliant.

How do I verify if my suppliers meet EUDR requirements?

Tools like TraceX give you a supplier dashboard where you can store, review, and flag incomplete or expired documentation automatically.

Here’s where many teams fall short: they collect geo-data but don’t validate it.

Use satellite imagery or third-party data layers to check if deforestation occurred after the December 31, 2020 cutoff.

Why it matters: A single flagged plot can hold up an entire shipment—even if everything else is in order.

How to verify no deforestation under EUDR?

Platforms like TraceX integrate satellite overlays directly into supplier profiles, helping you spot risk before it’s too late.

If your product combines inputs from multiple farms or regions, make sure every component is traceable.

What to watch for:

This is where most DDSs get flagged.

Using a digital traceability system like TraceX, you can map inputs to outputs, verify origin at every node, and generate batch-level DDS automatically.

You can’t manage what you can’t see. And you definitely can’t submit what you can’t prove.

EUDR risk assessment isn’t just a checklist—it’s a system. One that connects every point of data, documentation, and decision across your supply chain.

You’ve assessed the risk. Now comes the harder part: what are you actually going to do about it?

Because under EUDR, the EU doesn’t just want awareness—they want action. And more importantly, proof of it.

If you’re an exporter, importer, or global sourcing team trying to scale compliance across hundreds of suppliers or complex, blended batches, you’ve likely asked:

“How do we get control without slowing down trade?”

“How do we build confidence across our supply chain?”

“How do we stop small gaps from becoming shipment-stopping issues?”

Here’s how forward-thinking companies are answering those questions—and staying ahead of the regulation.

Don’t wait until you’re assembling a DDS to discover that your supplier doesn’t have valid plot coordinates. Start early—onboard suppliers with:

If your sourcing starts in the dark, compliance ends in the dark. Getting it right up front saves you from backtracking later.

Platforms like TraceX offer field-ready mobile apps that allow geo-tagging farms, even offline, and sync them into your traceability system.

Here’s the truth: most compliance risk isn’t because suppliers are hiding something—it’s because you’re not seeing it clearly enough.

Validate every batch before shipment using:

Don’t just verify the supplier—verify the batch. This reduces exposure and builds confidence when the EU requests supporting documentation.

If your team is still assembling Due Diligence Statements manually—copy-pasting documents, matching GPS points to Excel rows—it’s not just slow, it’s risky.

Automating DDS generation helps you:

TraceX connects your field data directly to DDS templates and integrates with TRACES, making submission a one-click process—not a four-day project.

Not all batches will pass on the first try. That’s okay—what matters is how you respond.

Set up workflows so that:

This avoids finger-pointing, last-minute firefighting, and compliance bottlenecks when deadlines loom.

Sourcing and compliance aren’t the same thing—and shouldn’t be managed by the same dashboard.

Role-based views give:

EUDR isn’t just a policy—it’s a process. The best way to mitigate risk isn’t to play defense. It’s to build a proactive, tech-enabled compliance engine that does the heavy lifting for you.

EUDR compliance isn’t just about submitting documents — it’s about proving, at scale, that your sourcing is deforestation-free, legally produced, and fully traceable. That’s where TraceX’s EUDR Compliance Platform comes in.

It’s more than a tool — it’s your digital backbone for risk-ready trade.

With TraceX, you don’t have to manually track every variable. The platform automatically flags risks using:

You spot issues before they delay your shipment or invalidate your DDS.

Discover how a global tire manufacturer used tech to trace rubber back to the plot, validate it with satellite data, and automate DDS submissions—without disrupting operations.

Read the Customer Story → How They Future-Proofed Their Exports

Creating a Due Diligence Statement (DDS) manually is time-consuming and error-prone. TraceX lets you:

No loose files. No missing metadata. Just fully verifiable documentation—ready when customs or certifiers ask for it.

Submitting your DDS to the EU’s TRACES platform is mandatory. But doing it manually every time?

That’s where mistakes and delays happen.

TraceX connects directly to TRACES via API, letting you:

It’s like having a compliance officer embedded in your tech stack.

Whether you’re a global exporter or an EU importer managing dozens of suppliers, TraceX gives you a bird’s-eye view of your compliance health.

No spreadsheets. No blind spots. Just complete clarity.

We get it—EUDR compliance can feel like trying to hit a moving target. With the regulation evolving, deadlines looming, and supply chains stretching across continents, it’s easy to fall into traps that seem minor—until a shipment is delayed, a DDS is rejected, or your product is flagged at customs.

These mistakes are preventable if you know where to look.

Let’s walk through the most common pitfalls we see across exporters, importers, and sourcing teams—and how to steer clear of them.

The mistake: Waiting for PDFs, Excel sheets, or scanned certificates to come through WhatsApp or email from a supplier you haven’t seen in person in two years.

Why it happens: You trust your network. They’ve delivered before. But the EU isn’t evaluating trust—they’re evaluating proof.

The risk: Missing metadata, unverifiable timestamps, and inconsistent document formats can invalidate your DDS—no matter how “legit” the document seems.

Fix it with tech: Use a digital onboarding and documentation system like TraceX, where supplier documents are uploaded, verified, and version-controlled with full traceability.

The mistake: Uploading a single GPS point instead of a true plot-level polygon that shows the actual boundaries of the farm.

Why it matters: EUDR compliance requires the EU to see exactly where the product was produced—and confirm no deforestation happened post-2020 within those boundaries.

What’s missing: GPS points are too vague. One coordinate can’t validate an entire supply plot.

Fix it with field tools: Equip field agents with mobile tools (like those in TraceX) that allow offline polygon mapping, synced directly to your traceability platform.

The mistake: Basing your risk assessment on last year’s country classifications or using general “low-risk” labels to justify lighter compliance.

The risk: Country classifications are dynamic, supplier histories evolve, and regulations shift. What was “low-risk” last quarter may not be anymore.

The consequence: You may under-report, under-verify, or overlook hidden risk—opening yourself to shipment rejections or legal scrutiny.

Fix it with real-time scoring: Use platforms like TraceX that update country risk levels and overlay supplier data with deforestation maps, audit results, and legal checks—automatically.

The mistake: Treating DDS like a customs document you generate at the last mile rather than a supply chain practice that starts at the farm.

Why this hurts: Rushed DDS creation leads to data gaps, missing signatures, and panic-mode document hunting.

The bigger risk: One delay can derail not just one shipment—but your entire customer relationship.

Fix it with continuous compliance: With TraceX, you track batches from sourcing to shipping in real time. So when it’s time to submit, everything’s already there.

The companies that win aren’t the ones submitting DDS the fastest. They’re the ones who build systems that prevent these pitfalls from happening at all.

You don’t need more checklists. You need a platform that:

In today’s global supply chains, uncertainty is part of the job. But with the EU Deforestation Regulation, what’s optional is not whether you take risk seriously—it’s whether you’re prepared to prove you’ve done your part. From plot-level geolocation to satellite-backed deforestation checks, your compliance isn’t just a document—it’s your license to trade. TraceX gives you the visibility, automation, and assurance to make EUDR due diligence not just doable, but repeatable and reliable at scale. Because in a world where regulations are rising and market access is tightening, the companies who build trust through traceability are the ones who win.

Yes. Even in low-risk countries, you’re still required to submit a Due Diligence Statement (DDS) and prove traceability, deforestation-free sourcing, and legal production. “Low risk” only reduces the chance of inspection—not your responsibility.

Digital traceability platforms help automate geo-data validation, supplier documentation checks, batch-level tracking, and satellite deforestation analysis—making DDS preparation and TRACES submission seamless.

If a batch is flagged, you’ll need to resolve gaps—such as missing polygon mapping, unclear supplier documents, or deforestation exposure—before submitting a compliant DDS. Tools like TraceX help escalate, track, and fix issues before they halt your shipment.