Contact: +91 99725 24322 |

Menu

Menu

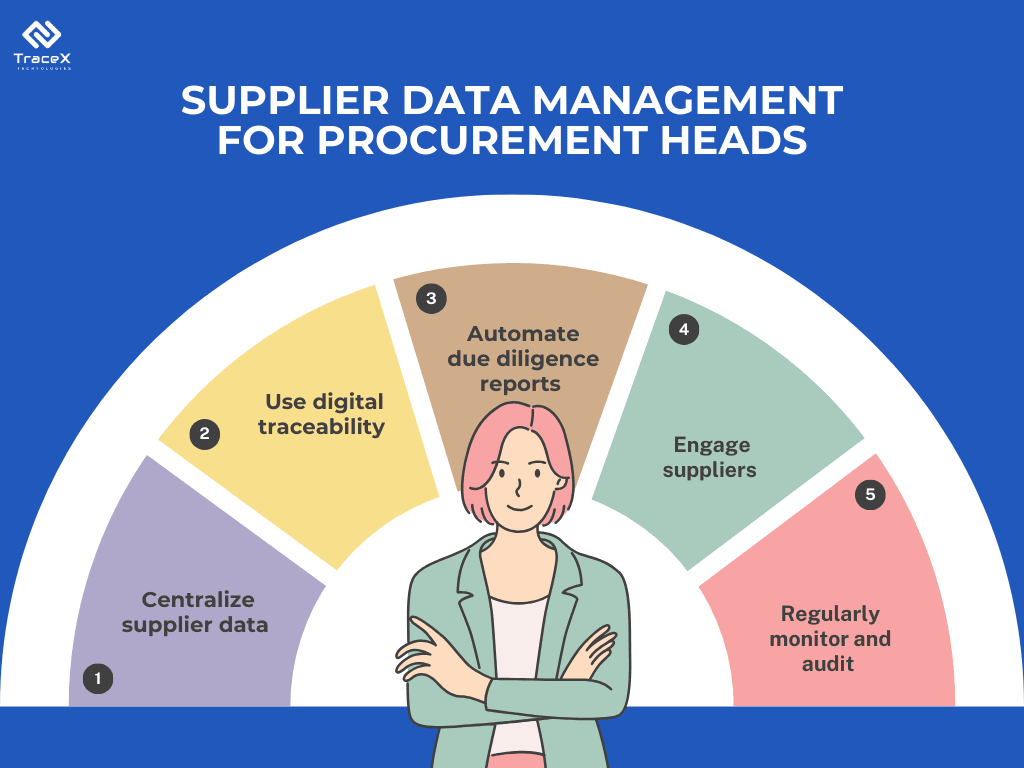

Quick summary: Learn how procurement heads can effectively manage supplier data for EU Deforestation Regulation (EUDR) compliance using advanced technology solutions. This guide explores key strategies to streamline data collection, verification, and reporting to ensure a deforestation-free supply chain.

Supplier Data Management in EUDR is the structured process of collecting, validating, and maintaining supplier information to meet the EU Deforestation Regulation’s traceability and legality requirements. Procurement heads must ensure geocoordinates of farms, proof of legal production, and risk assessments are accurately captured and updated. Centralized digital systems, standardized data formats, and regular audits help avoid gaps that could delay customs clearance or lead to noncompliance. By implementing robust Supplier Data Management in EUDR, procurement leaders enable faster due diligence, stronger supplier oversight, and a supply chain ready for 2026 compliance deadlines.

According to Deloitte’s findings, 82% of companies have integrated supplier risk evaluations into their data management practices, with the goal of recognizing and minimizing risks linked to suppliers.

At the heart of EUDR compliance challenge lies accurate supplier data. Without verified geocoordinates of production plots, legality documents, and UpToDate supplier records, even the most sophisticated companies cannot meet the due diligence requirements or generate the DDS reference number needed for customs clearance.

In this blog, we’ll dive into why Supplier Data Management in EUDR is critical, explore common data gaps and risks procurement teams face, outline best practices to manage supplier data efficiently, and highlight the tools and technologies that can help you build a compliant, traceable, and future ready supply chain.

Key Takeaways

The EUDR requires suppliers to provide geocoordinates of production plots, proof of legal land use, and risk assessments to ensure commodities are deforestation free and compliant before entering the EU market. Supplier Data Management in EUDR means systematically collecting, validating, storing, and updating this information across the supply chain.

The biggest challenges, data gaps, inconsistent formats, manual tracking, and lack of visibility, are solved by technology platforms that centralize records, automate checks, and integrate with ERPs. This leads to faster DDS preparation, fewer shipment delays, stronger supplier collaboration, and a supply chain fully ready for EUDR compliance.

Read our case study on How a Tire Company Future-Proofed Its Rubber Exports with EUDR Compliance to see how digital solutions and proactive compliance can transform your business and unlock smoother access to EU markets.

The EU Deforestation Regulation (EUDR) makes supplier data a nonnegotiable. To clear customs and secure market access, EU importers and operators must collect and maintain three critical categories of information:

Even if your business is outside the EU, your data flows directly into the EU buyer’s due diligence process. Without precise supplier records, EU customers cannot issue a valid Due Diligence Statement (DDS). This creates friction, delayed shipments, or even lost contracts.

Your competitive edge: being the supplier that delivers readytouse EUDR data makes you the preferred partner in highvalue markets.

Think of supplier data management for EUDR compliance not as a burden but as a gateway. By mapping suppliers and digitizing records now, you:

Static spreadsheets are no longer enough. EUDR demands live, verifiable supplier data—think mobile data capture in the field, cloud dashboards for updates, and integration with ERPs or farm management software.

By adopting dedicated platforms, procurement heads can:

EUDR is not just another regulation—it’s a new market reality. The sooner you master supplier data management for EUDR compliance, the sooner you unlock frictionless exports, stronger buyer confidence, and a resilient supply chain.

Want to master EUDR compliance?

Read our blog on Geolocation Requirements for EUDR to learn how accurate farm-level mapping ensures traceability and secures your supply chain.

Concerned about deforestation risks in your supply chain?

Explore our blog on Risk Assessment in EUDR to discover how identifying risks early can help you avoid penalties and build a stronger, compliant supply chain.

In the world of the EU Deforestation Regulation (EUDR), supplier data management isn’t just recordkeeping—it’s a strategic capability. It means building a centralized, structured system to capture, verify, store, and update every piece of supplier information needed to prove your products are deforestationfree and legally produced.

Before EUDR, many businesses relied on scattered spreadsheets, emails, and paper files. But when customs ask for geocoordinates, legality documents, and risk assessments, a fragmented approach leads to panic and delays.

Supplier Data Management in EUDR gives procurement teams one source of truth, eliminating lastminute scrambles and rejected shipments.

Strong supplier data management signals to the market that you care about transparency and sustainability. When you can instantly show where raw materials come from and that they meet EUDR criteria, you gain a reputation as a forward-thinking supplier.

Buyers increasingly choose partners with proven traceability systems.

Modern supplier data management uses digital platforms to:

Lastminute data gathering costs more—rush verifications, delayed shipments, demurrage fees. A proactive data management approach saves operational costs and protects margins.

The EUDR places a strong emphasis on due diligence, requiring businesses to prove that their products do not contribute to deforestation. This means gathering detailed information about your suppliers’ land-use practices, environmental policies, and sourcing methods—especially when working with commodities like palm oil, soy, coffee, and wood.

However, food and agribusiness supply chains are notoriously complex. Suppliers operate across different regions, often in remote areas with limited technological infrastructure. Data collection becomes fragmented, with inconsistent formats and reporting standards. As a result, procurement heads are left juggling multiple data sources, all while trying to ensure compliance and avoid fines or product rejections in the EU market.

Challenges addressed

Manual onboarding is slow and inconsistent → Digital SAQ captures all Article 9 & 10 data upfront.

Lack of EUDR-specific questions → Prebuilt SAQ ensures relevant data for compliance is collected.

Unclear supplier readiness → Self-declared readiness fields (GeoJSON, traceability, segregation) surface risks early.

Challenges addressed

Missing critical supplier identifiers → Capturing identity and operational data avoids record confusion.

Poor commodity mapping → Mapping to EUDRregulated commodities ensures no blind spots.

Lack of legal documentation and geolocation → Structured fields enforce complete, auditable datasets.

Uncertain tech adoption → Technology readiness fields reveal digital capability gaps.

Challenges addressed

Scattered documents across emails and folders → Centralized repository keeps everything accessible.

Manual document checks prone to errors → Automated crosschecks flag mismatched GeoJSON, expired certificates, and missing DDS.

Risk of using outdated compliance proofs → Expiry validations prevent lapses.

Challenges addressed:

No clear view of supplier compliance health → Scoring model (0–100) quantifies risk.

Hard to prioritize audits → Risk tiers (High/Medium/Low) drive targeted actions.

Reactive risk management → Proactive workflows trigger audits or remediation.

Challenges addressed

Onboarding done once and forgotten → 90day refreshes keep data current.

No historical context for audits → Audit trails track every communication and action.

Lack of collaboration on fixes → Shared workspace ensures both sides close gaps together.

Challenges addressed

Silent risks (deforestation, missing DDS) detected too late → Dynamic updates surface issues instantly.

Missed renewal deadlines → Alerts for certificate expirations and overdue DDS.

Supplier changes go unnoticed → Notifications when new suppliers or highrisk changes occur.

Challenges addressed

Double data entry across ERP/SRM → Direct sync keeps master data aligned.

Manual DDS submissions → EUIS integration pushes DDS automatically.

Lack of data visibility in client tools → APIs feed scores and statuses into dashboards.

Challenges addressed

Sensitive supplier data visible to all → Role-based permissions limit access.

Confusion in large, multi-country teams → Grouping by country, commodity, or unit organizes data.

No way for suppliers to manage their own docs → Self upload rights streamline updates and reduce admin load.

When supplier data is centralized and constantly updated, procurement teams can generate an EUDR compliant DDS in minutes—not weeks. No last-minute chasing for geocoordinates or legality documents.

In highly competitive markets, being able to ship first and clear customs faster isn’t just a compliance benefit—it’s a commercial advantage that protects revenue and builds buyer confidence.

Stronger Supplier Relationships Through Transparency

A structured data management system allows you to share back insights—like readiness scores or missing documentation—so suppliers know exactly what’s expected and how to improve.

Rather than treating compliance as a one way demand, you’re empowering your suppliers, which builds loyalty and shared accountability.

Real-time data validation flags issues before goods leave the origin country. For example, a missing certificate or imprecise GeoJSON polygon triggers an alert well before the container hits port.

Think of supplier data management as your insurance policy against portside surprises—you’re investing upfront to save huge operational costs later.

With accurate supplier data tied to commodities and regions, you can forecast inventory with confidence and produce credible sustainability reports that satisfy regulators, investors, and customers.

Data is not just for compliance—it’s a growth asset. Companies with transparent, traceable supply chains attract ESG-conscious buyers and investment.

TraceX EUDR Compliance Platform helps agribusinesses and exporters simplify compliance with the EU Deforestation Regulation. It combines AI-driven supplier data management, geospatial mapping, and real-time risk alerts to capture and validate farm-level information, generate accurate DDS submissions, and ensure traceability across complex supply chains. With automated document checks, supplier scoring, and seamless ERP integrations, the platform turns EUDR readiness into a scalable, easy to manage process that builds trust with EU buyers and reduces operational risk.

Mastering Supplier Data Management in EUDR isn’t just about avoiding penalties—it’s about building a resilient, transparent supply chain that EU buyers can trust. By investing in structured data collection, automated validation, and ongoing supplier engagement, procurement heads can turn regulatory pressure into a competitive advantage. Now is the time to adopt digital platforms, close data gaps, and position your organization as a preferred, EUDRready partner in global markets.

Is your supply chain ready for EUDR due diligence?

Read our blog on EUDR Due Diligence to understand how to gather the right data and ensure compliance before your goods hit the EU market.

Looking for the right tools to streamline EUDR compliance?

Explore our blog on EUDR Systems to learn about digital solutions that help manage supplier data and automate due diligence tasks.

How well do you know your suppliers’ risk?

Check out our blog on EUDR Supplier Risk Assessment to discover how to evaluate and manage risk to ensure your supply chain stays EUDR compliant.

It ensures all supplier information—geocoordinates, legality documents, risk scores—is captured and validated, enabling faster due diligence and audit readiness.

AI-enabled platforms like TraceX integrate with ERP systems to collect, store, and monitor supplier data in real time, reducing manual effort and errors.

Best practice is continuous monitoring with scheduled refreshes (e.g., every 90 days) to ensure readiness for audits and to catch risks before shipments.