Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Explore the complexities of the tomato supply chain and discover how challenges in production, post-harvest handling, and infrastructure impact the industry. Learn about innovative solutions like TraceX farm management software, offering insights to streamline processes and enhance sustainability.

From vibrant red salads to tangy sauces, tomatoes are a global culinary staple. But the journey from farm to table isn’t always smooth sailing. The tomato supply chain faces a multitude of challenges, threatening both the quality of this beloved fruit and the livelihoods of those who cultivate it.

The tomato supply chain faces a myriad of challenges that impact its efficiency, sustainability, and resilience. From production to distribution, various factors contribute to these challenges, affecting stakeholders at every stage of the supply chain. Understanding these challenges is crucial for implementing effective strategies to address them and ensure a reliable and sustainable tomato supply chain.

The global tomato market is a significant segment within the food and agricultural industries, valued at approximately USD 194.52 billion in 2022 and projected to reach around USD 300.84 billion by 2031, growing at a CAGR of 4.9% from 2023 to 2031 . Tomatoes are essential for various culinary applications worldwide, with a substantial portion consumed fresh and the remainder processed into products such as sauces, pastes, and canned tomatoes.

Key trends driving the global market include:

The global tomato processing market specifically reached 48.5 million tons in 2024, with expectations to grow to 64.6 million tons by 2033, reflecting a CAGR of 3.21% during the period from 2025 to 2033 . Europe currently dominates this market due to its robust food culture that heavily relies on tomato-based products.

India is one of the largest producers of tomatoes globally, with significant contributions to both fresh consumption and processing sectors. The country benefits from diverse climatic conditions that allow for year-round cultivation, making it a critical player in the global tomato supply chain.

Globally, India is the second-largest producer of tomatoes, with Madhya Pradesh (MP) being the leading producer in the country

The Indian tomato market faces challenges such as post-harvest losses due to inadequate infrastructure, fluctuating prices, and the need for improved supply chain management.

The tomato supply chain encompasses a complex network of activities involved in the production, processing, distribution, and retailing of tomatoes. It typically begins with cultivation on farms, followed by harvesting, sorting, packaging, transportation, and eventually reaches consumers through various retail outlets. This chain involves numerous stakeholders, including farmers, processors, distributors, retailers, and consumers, each playing a crucial role in ensuring a steady flow of tomatoes from farm to table.

The tomato supply chain is essential for meeting the global demand for this versatile and nutritious fruit. However, it faces various challenges that can disrupt its efficiency, sustainability, and profitability. These challenges range from production-related issues such as crop diseases and climate variability to logistical hurdles like transportation delays and market fluctuations. Addressing these challenges is crucial to ensure food security, minimize waste, maintain quality standards, and support the livelihoods of farmers and other stakeholders involved in the supply chain. In this section, we will delve deeper into the specific challenges facing the tomato supply chain and explore potential solutions to overcome them.

Tomato production faces various agronomic challenges, including pest and disease infestations, unpredictable weather patterns, and soil degradation. Pests such as aphids, whiteflies, and tomato hornworms can damage crops, leading to yield losses if not effectively managed. Likewise, diseases like blight, wilt, and viruses pose significant threats to tomato plants, requiring timely intervention through proper sanitation, crop rotation, and the use of disease-resistant varieties.

The indiscriminate use of agri-inputs such as fertilizers and pesticides can have adverse effects on soil health and environmental sustainability. Overuse of chemical fertilizers can lead to nutrient imbalances, soil acidification, and groundwater contamination, while pesticide residues may persist in the soil, water, and food chain, posing risks to human health and biodiversity. Promoting integrated pest management (IPM) practices, organic farming methods, and soil conservation techniques can help mitigate these risks and improve soil health in tomato production systems.

Achieving the desired quality standards for tomatoes is essential for market acceptance and profitability. Factors such as fruit size, shape, color, texture, and taste influence consumer preferences and market prices. However, maintaining consistent quality throughout the production cycle can be challenging due to factors like uneven ripening, fruit deformities, and post-harvest handling practices. Effective grading, sorting, and packaging techniques are critical to ensure that only high-quality tomatoes reach the market, thereby maximizing returns for growers and enhancing consumer satisfaction.

Losses incurred during harvesting, handling, and grading contribute to inefficiencies and waste in the tomato supply chain. Mechanical damage during harvesting, improper storage conditions, and inadequate transportation infrastructure can result in physical losses, reducing overall yields and marketable quantities. Furthermore, human errors in grading and sorting processes may lead to quality downgrade or rejection of produce, further exacerbating losses and lowering farmer incomes. Implementing proper harvesting techniques, investing in post-harvest infrastructure, and training workers on quality control measures can help minimize losses and improve the efficiency of the tomato supply chain.

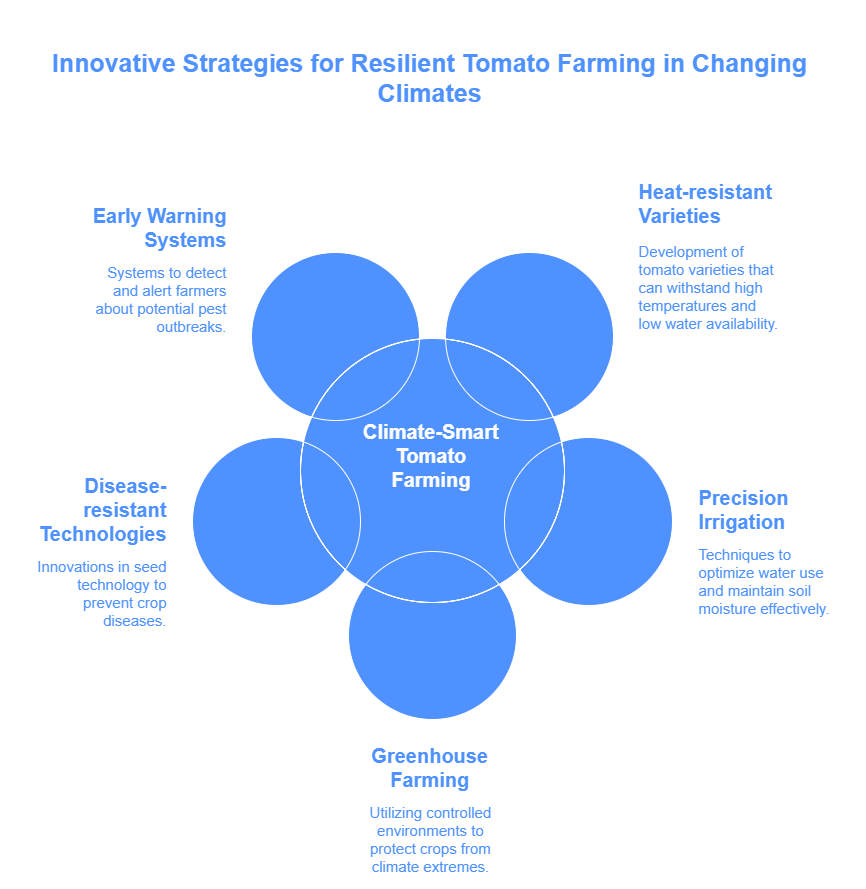

Tomatoes, one of the world’s most widely consumed crops, are highly sensitive to climate change. Rising temperatures, erratic rainfall, and extreme weather events are disrupting yields, affecting quality, and increasing production costs.

Higher temperatures accelerate tomato ripening, leading to smaller fruits with reduced shelf life. In extreme heat, pollen viability drops, reducing fruit set and yield.

In California, a key tomato-producing region, heatwaves have led to 15-20% yield losses in recent years. Farmers are shifting to heat-tolerant tomato varieties to adapt.

Inconsistent rainfall patterns and prolonged droughts stress plants, reduce productivity, and impact fruit quality. Tomatoes require stable moisture levels for optimal growth.

India’s tomato crisis (2023) saw erratic monsoons destroy crops, leading to a 400% price surge. Farmers are adopting drip irrigation and water-efficient techniques to mitigate risks.

Warmer temperatures create favorable conditions for pests like whiteflies, which transmit viruses such as Tomato Yellow Leaf Curl Virus (TYLCV). Fungal diseases like late blight also spread more aggressively in humid conditions.

Spain, a major tomato exporter, has faced higher pesticide costs as farmers battle rising pest infestations linked to climate change. Biological pest control and integrated pest management (IPM) are gaining traction.

Storms, floods, and hailstorms damage crops, disrupt supply chains, and increase post-harvest losses.

In Italy, heavy rains and floods in 2023 destroyed tomato fields, impacting both fresh and processed tomato markets. Producers are investing in greenhouse farming and protected cultivation for resilience.

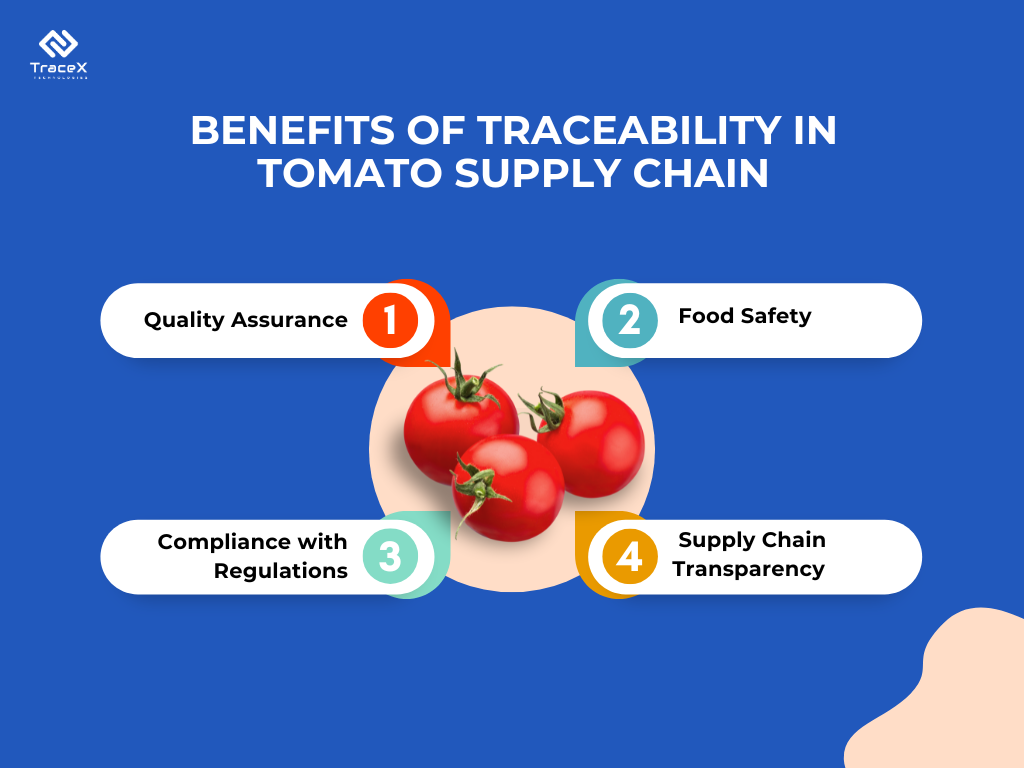

Innovative technological solutions are revolutionizing the tomato supply chain, offering promising avenues for addressing long-standing challenges. These advancements play a crucial role in enhancing efficiency, transparency, and traceability throughout the supply chain. By introducing cutting-edge traceability and digital solutions, such as blockchain-powered platforms and farm management software like TraceX, stakeholders can effectively track the journey of tomatoes from farm to fork. These technologies enable real-time monitoring of production practices, post-harvest handling, and transportation, facilitating better decision-making and quality control. With technology at the forefront, the tomato supply chain is poised for a transformative shift towards greater sustainability and resilience.

With TraceX Blockchain platform, farmers can now easily:

Here’s how TraceX Blockchain platform empowered CSAFE farmers:

By providing targeted information and guidance, TraceX empowered CSAFE farmers to move from overreliance on intuition to a more data-driven and sustainable approach to resource management. This shift has the potential to improve crop yields, boost profitability, and protect the environment.

Here’s how farm digitization with TraceX helped CSAFE farmers navigate post-harvest complexities:

By embracing farm digitization through TraceX, CSAFE farmers can now focus on delivering high-quality tomatoes to consumers. This not only benefits their own livelihoods but also contributes to a more efficient and sustainable food supply chain.

The future of tomato supply chain management holds exciting possibilities as emerging trends and innovations reshape the industry landscape. Stakeholders are increasingly leveraging technology to address existing challenges and unlock new opportunities for improvement. From blockchain-powered traceability solutions to AI-driven predictive analytics, the adoption of innovative tools promises to enhance efficiency, transparency, and sustainability across the supply chain. Additionally, there is growing recognition of the need for collaboration and partnerships to drive collective action and address systemic issues. As the industry continues to evolve, there are vast opportunities for innovation and improvement, paving the way for a more resilient and sustainable tomato supply chain.

In conclusion, the tomato supply chain faces multifaceted challenges across production, post-harvest handling, and infrastructure. These challenges, ranging from agronomy issues to insufficient cold chain infrastructure, contribute to inefficiencies and losses throughout the supply chain. However, with the advent of technology solutions like TraceX farm management software, there’s hope for overcoming these hurdles. By embracing digital solutions and innovation, stakeholders in the tomato supply chain can work towards a more resilient, efficient, and sustainable future.

The key challenges include climate variability, post-harvest losses due to inadequate cold chain infrastructure, fluctuating market prices, and disease outbreaks like the Tomato Brown Rugose Fruit Virus (ToBRFV). These issues impact both productivity and profitability for farmers and suppliers.

Digital solutions like blockchain-based traceability, AI-driven demand forecasting, and IoT-enabled cold chain monitoring can enhance transparency, reduce losses, and optimize logistics, ensuring better quality and sustainability.

Sustainable practices, such as regenerative agriculture, water-efficient irrigation, and carbon footprint reduction, are essential for improving long-term productivity and meeting consumer and regulatory demands for environmentally responsible sourcing.