Contact: +91 99725 24322 |

Menu

Menu

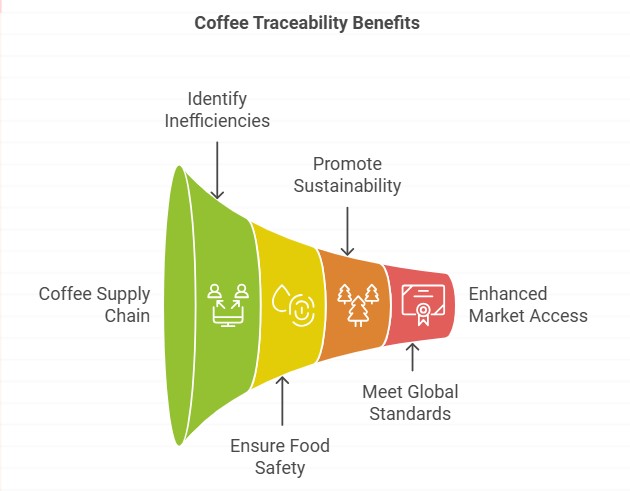

Quick summary: Discover the importance of coffee traceability in ensuring transparency, sustainability, and quality throughout the supply chain. Explore how traceability systems empower coffee producers, exporters, and retailers to make a positive impact on the industry. Dive into the world of coffee traceability and join the movement towards a more ethical and sustainable coffee experience.

Ever wondered about the story behind your morning coffee? Beyond its rich aroma and invigorating flavor lies a journey of hard work, sustainability challenges, and evolving consumer demands. Coffee traceability bridges these gaps, ensuring every sip supports sustainability, fairness, and quality.

Coffee ranks among the most loved beverages globally. This surprising statistic reveals that it is surpassed only by water. Annually, approximately 400 billion cups of coffee are consumed

Today’s coffee drinkers crave transparency, but the coffee supply chain is often a maze. From farms nestled in remote highlands to your cup, gaps in traceability make it difficult to guarantee ethical sourcing, fair wages for farmers, or sustainable practices. Without clear traceability, how can consumers trust the origins of their coffee or its impact on the planet?

Coffee begins its journey in lush, tropical regions across the globe, where the climate is just right. Countries like Brazil, Colombia, Ethiopia, and Vietnam are some of the world’s biggest coffee producers. Here, farmers grow coffee plants, which are delicate and require specific conditions—moderate temperatures, consistent rainfall, and nutrient-rich soil.

There are two primary coffee species: Arabica (known for its smooth, nuanced flavor) and Robusta (valued for its strong, bold taste). Farmers nurture these plants for years before they bear fruit, called coffee cherries.

When coffee cherries ripen, they turn bright red, signaling they’re ready to be picked. This can be done manually or mechanically, depending on the region and resources. Manual picking, common in many smaller farms, allows farmers to select only the ripest cherries, ensuring better quality.

Once harvested, the cherries must be processed quickly to avoid spoilage. Two common methods are:

After processing, what remains is the green coffee bean, ready for its next adventure.

Green coffee beans are bagged and shipped to roasters worldwide. This step is a logistical feat, as coffee often travels thousands of miles from the farm to reach its final destination. Exporters and importers ensure the beans remain fresh and uncontaminated throughout this journey.

At the roasteries, green beans are transformed into the aromatic coffee we recognize. The roasting process is an art and science, where precise temperature and time unlock flavors hidden within the beans. Light, medium, or dark roast? Each level creates distinct flavor profiles, catering to different preferences.

Once roasted, coffee is packaged and sold to consumers. From supermarket shelves to specialty coffee shops, it’s now ready to become part of your morning ritual.

Brewing methods, such as espresso, French press, or pour-over, allow coffee lovers to extract their perfect cup. But every sip you take is a testament to the hard work of countless hands along the supply chain—from the farmers who nurtured the plants to the baristas who pour the brew.

The coffee supply chain is a story of global collaboration and craftsmanship, ensuring that the simple pleasure of coffee remains accessible and enjoyable for millions worldwide.

Today’s coffee drinkers care about more than just taste; they want to know where their coffee comes from. Eco-conscious customers seek assurance that their favorite brew supports ethical and sustainable practices. Traceability provides a clear “bean-to-cup” story, allowing brands to connect with consumers who prioritize sustainability and quality. For many, seeing a QR code that details the farm of origin, farmer details, and production practices adds immense value.

The coffee industry involves millions of small-scale farmers worldwide, many of whom face challenges such as low wages and poor working conditions. Traceability systems can help ensure fair wages and ethical labor practices. Additionally, these systems can identify supply chain segments that contribute to deforestation or biodiversity loss, enabling businesses to address these issues proactively.

Coffee traceability is essential for achieving sustainability in the sector. It allows stakeholders to monitor and promote practices like organic farming, agroforestry, and water conservation. By tracking the environmental impact of coffee production, companies can contribute to conserving ecosystems and protecting biodiversity.

For example, traceability systems can highlight farms employing sustainable techniques, such as shade-grown coffee cultivation, which supports wildlife habitats.

Regulations like Fair Trade, Organic Certification, and the EU Deforestation Regulation (EUDR) demand rigorous supply chain documentation. Coffee traceability ensures compliance with these standards by tracking each stage of production, from the farm to the consumer.

For businesses, this means avoiding penalties, accessing new markets, and aligning with international sustainability goals. For consumers, it reinforces trust in their favorite coffee brands.

By integrating coffee traceability into the supply chain, the industry ensures a win-win for farmers, businesses, and consumers while championing ethical and sustainable practices on a global scale.

Technoserve partnered with TraceX to introduce an end-to-end digital traceability solution for 3,500 coffee farmers in India’s Araku Valley. This collaboration focuses on creating transparency across the coffee supply chain, enhancing data management, and fostering sustainable and ethical practices. By leveraging advanced technology, the initiative empowers smallholder farmers with better visibility, aligns production with sustainability goals, and strengthens consumer trust in the journey from bean to cup. This case exemplifies the transformative potential of technology in driving sustainability and ethical practices in agriculture.

The TraceX Food Traceability Platform is a blockchain-enabled solution designed to bring transparency, accountability, and sustainability to the food supply chain. It ensures end-to-end traceability, allowing stakeholders to monitor, verify, and optimize every stage of production and distribution.

TraceX is transforming the food industry by fostering trust, reducing waste, and driving sustainable practices across global supply chains.

Coffee traceability is more than just a supply chain buzzword—it’s a transformative approach to ensuring quality, sustainability, and ethical practices from farm to cup. By leveraging advanced technologies like blockchain and IoT, businesses can overcome challenges in data collection and compliance, meeting the expectations of eco-conscious consumers while promoting sustainability and fair trade. Traceable coffee builds trust, empowers stakeholders, and ensures every cup you enjoy tells a story worth sharing.

Coffee traceability ensures transparency across the supply chain, enabling consumers to verify the origin, quality, and ethical standards of their coffee. It also helps businesses adhere to sustainability and regulatory requirements.

Technologies like blockchain, IoT sensors, and GPS mapping are used to record, track, and verify data at each stage of the coffee supply chain.

Traceability promotes sustainable practices by tracking deforestation risks, encouraging fair wages for farmers, and ensuring compliance with global standards like organic , rainforest alliance certified and fair trade certifications.