Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Discover how to tackle EUDR compliance challenges in warehouse management. Learn how transparency, traceability, and blockchain technology can streamline your supply chain and ensure compliance with the EU Deforestation Regulation (EUDR)

Warehouse Management plays a crucial role in global supply chains, but under the new European Union Deforestation Regulation (EUDR), their responsibilities are expanding. Beyond simply storing goods, warehouses now face the complex task of ensuring that products meet stringent deforestation-free requirements. Many warehouses are still grappling with outdated systems and manual processes that make it difficult to track product origins, leaving them vulnerable to non-compliance. Failure to comply with EUDR could result in heavy fines, damaged reputations, and even exclusion from the EU market.

At the heart of EUDR compliance lies the need for robust warehouse management systems. Warehouses, which often aggregate goods from multiple suppliers, must now handle more than just logistics—they are tasked with managing traceability, transparency, and ensuring all products meet regulatory standards

This shift presents a significant challenge for businesses that aggregate and distribute commodities like coffee, cocoa, soy, and palm oil. How can you ensure compliance while managing thousands of products from different suppliers? For warehouse managers, navigating this landscape requires more than just logistics expertise—it demands robust traceability systems, real-time monitoring, and automated compliance documentation.

Key Takeaways

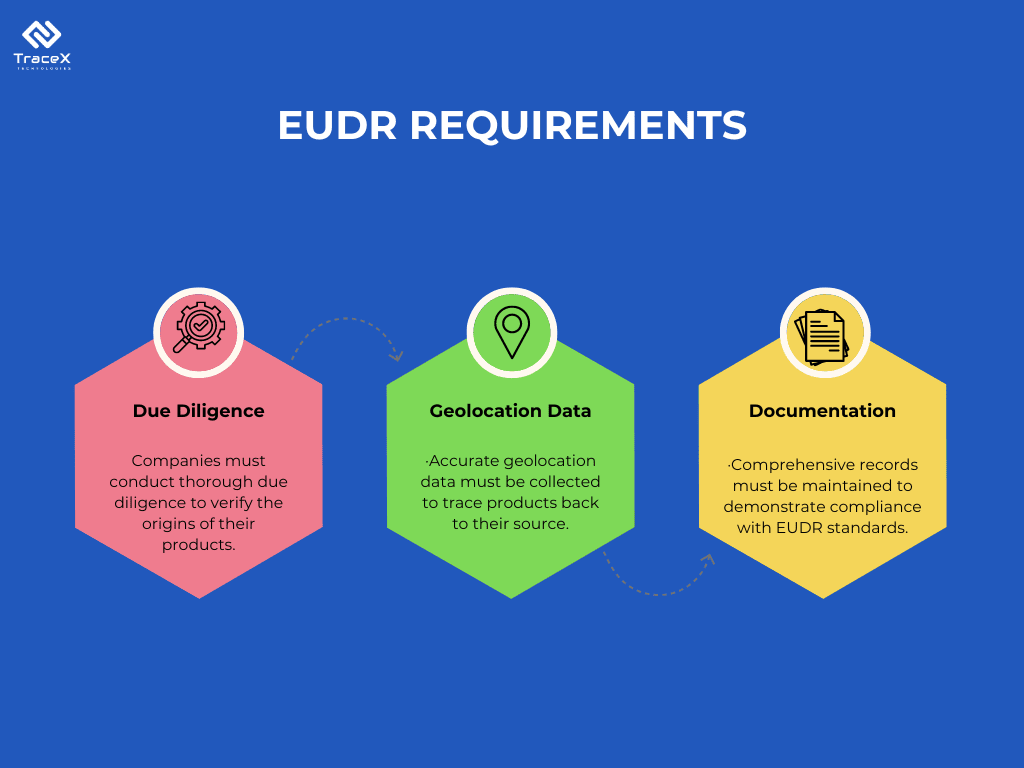

The European Union Deforestation Regulation (EUDR) aims to prevent the import of products linked to deforestation into the EU market. It mandates that companies ensure their supply chains are free from deforestation, demanding full traceability and due diligence on product origins. This affects several sectors, including coffee, cocoa, soy, and wood, forcing businesses to overhaul their supply chain management. For companies dealing with warehouses and logistics, EUDR creates challenges like tracking each product’s origin, aggregating data, and ensuring compliance across multiple suppliers, all while maintaining operational efficiency.

Before diving into the specifics of warehouse management, it’s essential to understand the scope of EUDR and why it matters. The EUDR aims to prevent products linked to deforestation from entering the EU market. This means businesses must provide verifiable proof that the products they sell are not sourced from deforested areas. For example, coffee roasters need to trace their beans back to the farm to ensure compliance. While this level of transparency benefits the environment and promotes ethical sourcing, it adds layers of complexity for warehouse managers.

Warehouse management plays a crucial role in the effectiveness and efficiency of supply chains, especially as regulations like the European Union Deforestation Regulation (EUDR) come into play. The EUDR compliance aims to prevent the import of commodities linked to deforestation, requiring businesses to ensure that their products are sourced sustainably

Effective warehouse management systems (WMS) facilitate traceability by:

Data governance is critical under the EUDR. Warehouse management plays a key role in this area:

Warehouse management systems can help identify risks associated with non-compliance

Effective warehouse management supports supplier accountability

One of the core requirements of EUDR is tracking the geographic origin of products. This is where GeoJSON, a standard format for encoding geographic data, plays a crucial role. Warehouses that aggregate products from different suppliers need to track the geographic data of every batch, ensuring that each item meets deforestation-free requirements.

The Problem

Many warehouses, especially those handling large quantities of products from various regions, struggle to maintain the integrity of geographic data. Once products are aggregated, the risk of losing track of their origin increases. For example, a warehouse managing palm oil from multiple suppliers may accidentally mix compliant and non-compliant batches, leading to significant compliance risks.

The Solution

The use of traceability platforms, like blockchain-based solutions, can solve this issue. These platforms assign unique digital identifiers to each product, ensuring that geographic origin data is preserved even when products are aggregated. By adopting this technology, warehouse managers can easily retrieve data, confirm compliance, and avoid the risks associated with losing track of product origins.

For example, a coffee roaster sourcing beans from Colombia can use a traceability platform to ensure that the beans are not mixed with those from a deforested area. This not only guarantees compliance but also builds trust with consumers, who are increasingly concerned about ethical sourcing.

Many warehouses still rely on legacy management systems, which may not support the advanced traceability features required for EUDR compliance. These outdated systems can struggle to process and store geographic data, making it difficult to provide proof of compliance during audits.

The Problem

Legacy systems are often siloed and difficult to integrate with modern technologies like blockchain or real-time monitoring tools. This lack of integration can lead to delays in reporting and difficulties in accessing compliance-related data, making audits time-consuming and inefficient.

The Solution

Investing in integrated supply chain management software is key to overcoming this challenge. These systems are designed to work seamlessly with existing warehouse management solutions while incorporating new technologies for traceability and compliance. Additionally, cloud-based platforms enable warehouses to store and retrieve compliance documentation quickly, ensuring that they are always audit-ready.

For example, a rubber supplier can integrate their warehouse management system with a blockchain-based solution. By doing so, they can monitor the origin of every shipment in real time, ensuring that only compliant products enter the EU market.

Warehouses often aggregate products from multiple suppliers, which can complicate compliance efforts. For example, a warehouse handling soybeans from various farmers may face difficulty proving that each batch comes from a deforestation-free source.

The Problem

When products from different suppliers are aggregated, there’s a risk of mixing compliant and non-compliant goods. This can make it nearly impossible to trace the origin of specific batches, leading to non-compliance with EUDR regulations.

The Solution

To solve this issue, warehouses need to implement granular tracking systems that can monitor the origin of each product, even when aggregated. These systems can assign unique identifiers to each batch, ensuring that geographic data is never lost during the aggregation process.

For example, a soybean exporter can use a traceability platform to track each batch’s origin, ensuring that products from deforested areas are flagged and excluded from the EU supply chain. This allows the warehouse to aggregate products while maintaining full transparency and traceability.

In the context of EUDR, real-time monitoring is essential for ensuring continuous compliance. Warehouses need to monitor products as they move through the supply chain, flagging any issues before they reach the EU market.

The Problem

Many warehouses lack the tools necessary to monitor product movements in real time. As a result, they may miss important compliance issues, such as a product sourced from a deforested area. This can lead to costly delays, fines, and damage to the company’s reputation.

The Solution

Real-time monitoring systems, such as those powered by IoT and blockchain technology, can provide warehouses with the tools they need to stay ahead of compliance issues. These systems enable warehouses to track products from the farm to the EU border, ensuring that non-compliant products are flagged before they enter the market.

For example, a cocoa exporter using a blockchain-based monitoring system can receive real-time alerts if a shipment originates from a deforested area. This allows the company to take corrective action before the product reaches the EU, ensuring compliance with EUDR regulations.

One of the most time-consuming aspects of EUDR compliance is the documentation process. Warehouses must provide detailed records proving the geographic origin of products, and these records must be readily available for audits.

The Problem

Many warehouses still rely on manual processes for compliance documentation, which can be inefficient and error-prone. This can lead to delays during audits and increase the risk of non-compliance.

The Solution

Automation is the key to solving this challenge. By using a digital traceability platform, warehouses can automate the documentation process, ensuring that all necessary records are stored securely and can be retrieved with ease. This reduces the time and effort required for audits, while also ensuring that documentation is accurate and up to date. EUDR reporting ensures that companies in the EU maintain transparency by providing verifiable data on their supply chains, proving that the sourcing of specific commodities like coffee, soy, or palm oil does not contribute to deforestation. This documentation is critical for meeting compliance and avoiding penalties under the EU Deforestation Regulation.

For example, a palm oil supplier can use a blockchain-based platform to automatically store all compliance-related documents in the cloud. When an audit request comes in, the company can retrieve all necessary documents within minutes, greatly reducing the time and effort required for the audit process.

The TraceX EUDR compliance platform provides essential solutions to the challenges of warehouse management under the EU Deforestation Regulation .

1. Traceability at the Source Level:

With EUDR requiring proof of deforestation-free origins, TraceX enables real-time tracking of every batch’s origin, down to individual farms or regions. For warehouses handling large volumes of products, this ensures each shipment can be traced back to its deforestation-free source, reducing compliance risks.

2. Automated Data Aggregation and Reporting:

Warehouse operations often deal with numerous suppliers and large inventories, making manual data tracking complex. The TraceX platform automates the aggregation of geo-location data, batch records, and origin details, streamlining warehouse management for compliance. This reduces the burden of manually collating data and preparing reports for audits.

3. Blockchain for Secure and Tamper-Proof Documentation:

EUDR requires businesses to maintain comprehensive records that verify compliance, such as product certifications and origin proofs. TraceX uses blockchain technology to store all documentation securely and transparently, ensuring that records are tamper-proof and easily accessible during audits.

4. Real-Time Alerts and Risk Mitigation:

For warehouse managers, keeping track of products from deforestation-risk regions can be overwhelming. TraceX provides real-time alerts when potential non-compliant batches are detected, allowing businesses to address issues immediately and prevent non-compliant products from entering the supply chain.

5. Seamless Integration with Existing Systems:

Many warehouses already use different inventory management systems, and integrating new compliance tools can be a challenge. TraceX’s platform integrates seamlessly with existing warehouse management software, ensuring minimal disruption while enabling robust compliance tracking.

6. Sales Order generation

Multiple batches of consignment sales can be recorded alongside the sales order. When a container is filled, essential details such as Shipment ID, Bill of Lading ID, Container ID, HSN Code, Qty Shipped, Date of Shipment, From Location, To Location, and more will be documented in TraceX as part of Proforma Sales. After creating the ‘Proforma Sales,’ the final geoJson for each container, along with a DDS Statement, can be downloaded and provided to the importer or downstream parties. The importer can then utilize the furnished GeoJSON to upload to the EU-IS portal for DDS filing requirements.

By leveraging these features, TraceX helps agribusinesses and warehouse managers efficiently meet EUDR requirements, reducing risks and streamlining compliance processes for smoother, more transparent operations.

Warehouse management under the EUDR is no longer just about logistics—it’s about ensuring compliance with strict environmental regulations. The challenges are significant, but they can be overcome with the right technology and processes.

By implementing digital traceability systems, integrating legacy systems with modern tools, and automating compliance documentation, warehouses can not only meet EUDR requirements but also improve overall efficiency. As the regulatory landscape continues to evolve, investing in these solutions will be critical for businesses looking to maintain their foothold in the EU market.

The European Union Deforestation Regulation (EUDR) requires businesses to prove that their products are not linked to deforestation. For warehouses, this means managing traceability, geographic data, and compliance documentation to ensure that all products meet regulatory standards.

Digital traceability platforms, especially those powered by blockchain technology, enable warehouses to track the geographic origin of products, monitor real-time compliance, and automate documentation processes. This ensures transparency and reduces the risk of non-compliance.

Non-compliance with EUDR can result in fines, delays, and even exclusion from the EU market. Businesses that fail to provide adequate documentation proving the geographic origin of their products may face significant penalties and damage to their reputation.