Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Uncover the essentials of tracking materials across the supply chain, from origin to final product. Gain insights into the significance of material traceability, its impact on quality, compliance, and sustainable practices. Elevate your understanding and optimize your supply chain with this insightful read. Explore now for a deeper insight into material traceability in modern supply chains.

In the globalized market, consumers and regulators alike are demanding greater transparency about where products come from and how they’re made. But for many companies, tracking materials from their origin to the end product is easier said than done. The challenge? Gaps in material traceability can result in compliance risks, quality issues, and a lack of consumer trust. Without a clear view into their supply chains, businesses struggle to prove the ethical and sustainable sourcing of materials, potentially leading to costly disruptions and reputational damage.

Key Takeaways

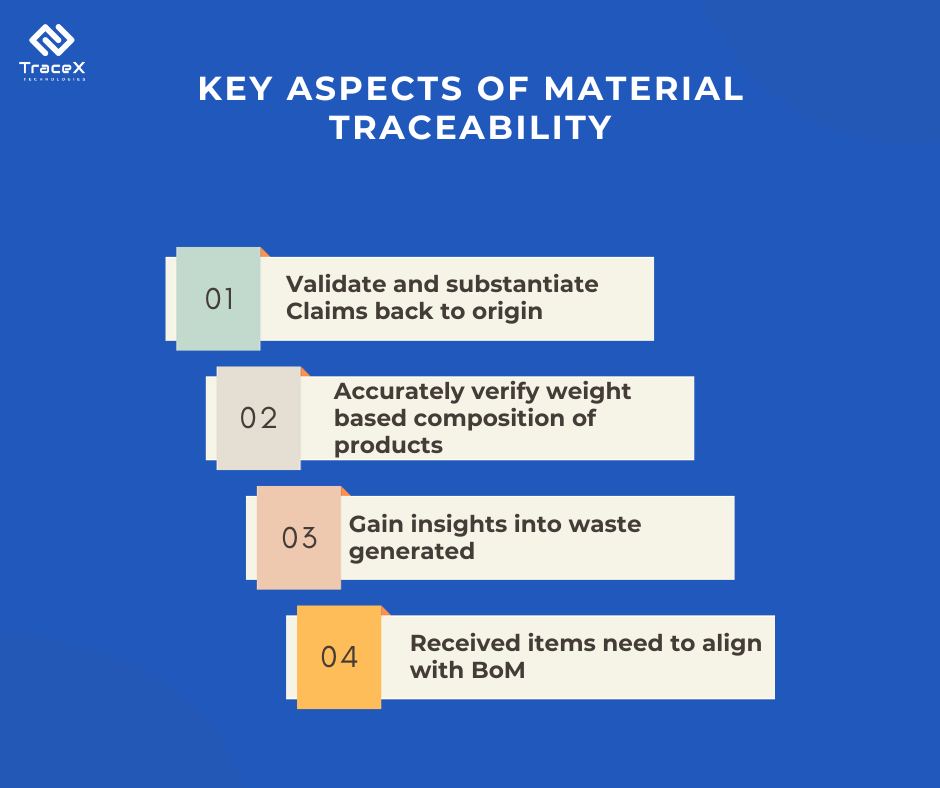

Supply chain traceability is a critical aspect of material traceability, ensuring that every component and raw material can be tracked from its origin to the final product. It provides visibility into the journey materials take through each stage of production, processing, and distribution.

Material traceability is about more than just tracking goods from point A to point B; it’s about understanding the story behind each material. It’s the tale of its origin, the people involved, and the journey it embarks upon. At its core, material traceability is a commitment – a commitment to quality, ethics, and the well-being of both the business and the end consumer.

In recent times, the significance of traceability has escalated for manufacturing enterprises. The proliferation of global supply chains has added complexity to ensuring that products adhere to quality standards and comply with regulations. Material traceability has emerged as a pivotal strategy, enabling companies to detect potential issues early in the production processes and implement corrective measures proactively, averting major problems.

Moreover, traceability plays a vital role in managing product specifications and their dissemination to factories and subcontractors. By meticulously tracking the distribution of specifications for materials and products, companies can verify adherence to standards, ensuring that factories and suppliers are in compliance. Material traceability goes beyond mere serial- and batch control; it stands as a crucial contributor to the development of digital threads and digital twins in the manufacturing landscape.

The significance of material traceability resonates from diverse perspectives, each contributing to the overall success and sustainability of businesses.

Material traceability extends its influence across the entire supply chain, impacting various stakeholders and processes.

Material traceability plays a crucial role in complying with the European Union Deforestation Regulation (EUDR). The EUDR aims to prevent the import of products linked to deforestation and forest degradation into the EU market. To meet these regulations, companies must ensure that the raw materials used in their products, such as soy, palm oil, coffee, cocoa, wood, and rubber, are sourced from land that is not deforested after December 31, 2020.

Elevate your commitment to quality and sustainable sourcing of cocoa just like this Nigerian firm. Ensure EUDR compliance, enhance data accuracy, and achieve complete material traceability with our solution.

Material traceability involves tracking the entire journey of these materials—from the origin at farms or forests, through processing and transportation, to the final product. This detailed tracking enables companies to verify that their supply chains are deforestation-free, providing evidence of compliance with EUDR requirements. By maintaining accurate records and documentation at every stage, companies can create a transparent and verifiable chain of custody, reducing the risk of penalties, supply chain disruptions, or loss of market access due to non-compliance.

The adoption of material traceability yields a multitude of benefits that extend beyond compliance requirements.

Technology solutions play a crucial role in overcoming the challenges of material traceability, offering greater transparency, efficiency, and reliability in tracking materials throughout the supply chain:

1. Blockchain for Secure Data Management: Blockchain technology enables secure, tamper-proof records of each transaction within the supply chain. It creates a decentralized ledger that ensures every step in the material’s journey is accurately recorded and verified, making it easier to prove compliance with regulations like the EUDR.

2. IoT Sensors and Smart Tags: Internet of Things (IoT) devices, such as sensors and RFID tags, can be used to track materials in real-time, providing accurate location and condition data. This helps businesses monitor the movement and storage conditions of raw materials, reducing the risk of data inaccuracies and ensuring quality control.

3. Digital Platforms for Centralized Data: Cloud-based platforms allow for the aggregation of data from multiple suppliers and stakeholders into a single, centralized system. This enables companies to break down data silos, offering a complete view of their supply chains and facilitating easier access to material data.

4. AI and Predictive Analytics: Artificial intelligence and machine learning can analyze supply chain data to predict risks, identify patterns, and optimize the sourcing process. This allows companies to anticipate potential disruptions and make more informed decisions about their material sourcing and logistics.

5. Automated Documentation and Reporting: Technology solutions automate the collection, documentation, and reporting processes for material traceability. This not only reduces manual effort and errors but also ensures that companies can provide necessary proof of traceability during audits and inspections.

6. Remote Sensing and Satellite Monitoring: Satellite imagery and remote sensing technology help monitor environmental conditions and land-use changes at the source of raw materials. This is particularly useful for verifying that materials like timber or palm oil are sourced from non-deforested land, aiding compliance with sustainability regulations.

The TraceX traceability platform is designed to enhance material traceability, providing a seamless way to track raw materials throughout the entire supply chain, from their origin to the final product. Utilizing blockchain technology, it ensures that every transaction and movement of materials is recorded in an immutable ledger, offering a transparent and tamper-proof record. This is especially critical for compliance with regulations like the EU Deforestation Regulation (EUDR), where companies must prove that materials like soy, palm oil, and rubber are sourced from non-deforested lands. TraceX enables businesses to trace the materials at each stage—farming, processing, and distribution—ensuring that they meet sustainability criteria and regulatory requirements. This not only simplifies compliance but also helps companies build trust with consumers by providing verifiable information about the origin and sustainability of their products.

Material traceability is not merely a logistical necessity but a strategic imperative for businesses navigating the complexities of modern supply chains. From compliance and risk mitigation to ethical sourcing and consumer trust, material traceability weaves a thread that connects stakeholders across the entire supply chain. As technologies continue to evolve, businesses embracing and investing in robust material traceability systems are not only meeting current expectations but are also laying the foundation for a sustainable and responsible future. In the intricate tapestry of global commerce, understanding the path of materials is not just a requirement – it’s the key to unlocking a future where transparency, accountability, and ethical practices reign supreme.

Material traceability refers to the ability to track the journey of raw materials throughout the supply chain, from their origin to the final product. This process involves documenting every step, including sourcing, processing, and distribution, to ensure transparency and compliance with regulations.

Material traceability is crucial for businesses as it helps ensure compliance with regulations, mitigates risks related to quality and sourcing, and enhances consumer trust. It also supports ethical sourcing practices, allowing companies to demonstrate their commitment to sustainability and responsible business practices.

Technology improves material traceability through solutions like blockchain, IoT sensors, and digital platforms that enable real-time tracking and secure data management. These tools facilitate accurate record-keeping, reduce manual errors, and provide transparency, making it easier for businesses to comply with regulations and meet consumer expectations.