Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Explore the palm oil supply chain, its challenges, and how traceability and technology-driven solutions can drive sustainability in agribusiness.

Imagine walking through a supermarket. You grab your favorite snacks, beauty products, maybe even a bottle of shampoo. But did you know that all these products might share a common ingredient—palm oil? In fact, the palm oil supply chain is so vast and integrated that this oil ends up in nearly half of all packaged products, from cookies and chocolates to soaps and cosmetics. This makes palm oil one of the most widely used and impactful vegetable oils on the planet.

84 percent of the world’s palm oil is produced by two countries Indonesia and Malaysia

This highly sought-after oil comes at a significant environmental and social cost. The explosive demand for palm oil has fueled widespread deforestation, particularly in tropical regions like Indonesia and Malaysia. Forests are being cleared at alarming rates, threatening ecosystems, endangering species like orangutans, and releasing large amounts of greenhouse gases. Beyond the environmental concerns, palm oil production often comes with labor issues—workers face challenging conditions, and small farmers struggle to compete with big corporations.

The goal of this article is simple: to pull back the curtain on the palm oil supply chain and explore how sustainable practices can address these pain points. From sourcing to manufacturing, we’ll look at what can be done to create a transparent and responsible supply chain, ensuring that the products we use daily contribute to a better future.

Key Takeaways

Palm oil has become incredibly popular, and it’s easy to see why. First off, it’s remarkably efficient in terms of land use. A single hectare of oil palm can produce more oil than almost any other vegetable oil crop—about four to ten times more than soy or sunflower. This means we can get a lot of oil with less land, which makes it economically attractive for both farmers and companies.

But it’s not just about yield; palm oil is extremely versatile. It has a smooth texture, remains semi-solid at room temperature, and has a longer shelf life, making it ideal for a variety of products. In food, it’s used for frying, baking, and in processed foods like cookies, ice cream, and instant noodles. It’s also a common ingredient in cosmetics, soaps, and even biofuels. This versatility has made palm oil a staple in many industries.

Finally, palm oil production has been a big economic driver for countries like Indonesia and Malaysia, which produce around 85% of the world’s supply. The industry supports millions of jobs, from small farmers to larger plantations, bringing income to rural areas and contributing to national economies. This economic importance makes it challenging to replace, even as sustainability concerns grow.

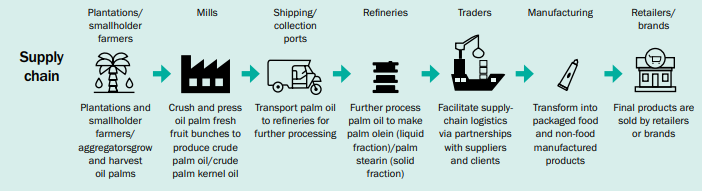

Let’s dive into how palm oil gets from plantation to product! Understanding these stages helps clarify why sustainability is a challenge in the palm oil industry.

The journey begins with cultivation. Growing oil palms requires specific tropical climates, which is why most palm oil is produced in Indonesia and Malaysia. To start, land is cleared and prepared, and then young palm trees are planted. This phase can be controversial since land preparation sometimes leads to deforestation, which impacts biodiversity and contributes to greenhouse gas emissions.

Once planted, these trees take about three years to mature, after which they start bearing fruit. Managing the plantation involves regular maintenance to ensure the palms remain healthy and productive. Fertilizers, pest control, and careful water management are part of this stage to achieve high yields.

When the oil palm trees are ready, the fruit is harvested—a process that’s labor-intensive. Workers use long poles with attached sickles to cut the fruit bunches from tall trees, a skill that requires experience. Since oil palm fruit is harvested year-round, there is a continuous need for labor, which can be challenging, especially during peak seasons. Harvesting practices impact the quality of the oil, as fruit needs to be processed within 24 hours to maintain freshness and avoid spoilage.

Once harvested, the fruit is sent to a mill where the actual processing begins. Here, the fruit is sterilized with steam to soften it, then stripped from the bunch and pressed to extract crude palm oil (CPO). This is a crucial step because any delay or poor handling can affect the oil’s quality. Quality control is key to ensure that the oil meets industry standards, and waste products, such as palm kernel shells, can be repurposed for energy or other uses. Processing is usually done close to plantations to reduce transportation time, as fresh fruit needs to be processed quickly.

Next, the crude palm oil goes through refining to become the edible oil we find in products. This process removes impurities, odours, and colours, resulting in refined palm oil that’s suitable for food and other uses. After refining, the oil is transported to various destinations, both locally and internationally. Distribution logistics can impact the final cost, which is why efficient transport and handling are essential.

Finally, refined palm oil reaches manufacturers who use it in a variety of products, from snacks and cooking oils to cosmetics and soaps. Palm oil’s versatility and long shelf life make it a preferred ingredient in numerous sectors. Retailers then bring these products to market, where consumers encounter palm oil in forms that may not be immediately obvious. Labeling and awareness are increasingly important here, as consumers want to know if their products are sourced sustainably.

Each stage in the palm oil supply chain presents unique challenges and opportunities. By improving transparency and implementing sustainable practices, stakeholders can address environmental concerns, labor issues, and quality control, ensuring a more responsible supply chain.

The palm oil industry is facing significant challenges that impact the environment, society, and business operations.

The palm oil supply chain faces complex challenges that require collaboration between companies, governments, and consumers to overcome. Environmental impacts, labor issues, traceability difficulties, and regulatory hurdles are all part of the landscape. Making the palm oil industry more sustainable is not easy, but every small step—like supporting fair labor or investing in traceability technology—moves the industry closer to a more ethical and sustainable future.

Consumers and regulators demand greater accountability, especially in complex industries like palm oil. Ensuring traceability and transparency in the palm oil supply chain is crucial for creating a sustainable future

Why does it matter where palm oil comes from? Knowing the origin of palm oil is essential for a few reasons:

Tracking palm oil through a multi-stage, multi-country supply chain can sound like a daunting task. But with the right technology, it becomes much more achievable. Here’s how:

The TraceX EUDR Compliance Platform is designed to help agribusinesses and exporters meet the requirements of the European Union Deforestation Regulation (EUDR). Leveraging blockchain technology, it provides end-to-end traceability for agricultural commodities, ensuring transparency and accountability throughout the supply chain. The platform enables companies to monitor, document, and verify the origins of their products, particularly from high-risk areas, by providing immutable records that facilitate compliance with deforestation-free sourcing mandates. This helps businesses mitigate risks, improve supply chain visibility, and demonstrate adherence to international sustainability standards, ultimately supporting their commitment to ethical and sustainable practices.

Certifications play a key role in promoting sustainable practices within the palm oil industry. By adhering to standards and obtaining certifications, companies can demonstrate their commitment to reducing environmental impact and improving social outcomes. Here are a few major certifications and standards that guide sustainable practices in palm oil:

The Roundtable on Sustainable Palm Oil (RSPO) is one of the most recognized certifications in the industry. For a company to be RSPO-certified, it must meet strict criteria that cover various aspects of production, including environmental protection, social responsibility, and transparency.

Being RSPO-certified means the company’s palm oil is produced without contributing to deforestation, environmental damage, or exploitation of workers. RSPO certification is significant because it assures consumers and businesses that the palm oil in their products meets rigorous sustainability standards. RSPO’s standards also encourage fair treatment of workers and respect for the rights of local communities, adding a layer of social responsibility to environmental protection.

RSPO certification has become a well-known symbol for responsible palm oil, allowing companies to build trust with environmentally conscious consumers and access markets that prioritize sustainability.

In addition to RSPO, Indonesia and Malaysia—the two largest palm oil producers—have developed their own certification standards: Indonesian Sustainable Palm Oil (ISPO) and Malaysian Sustainable Palm Oil (MSPO), respectively.

1. ISPO (Indonesian Sustainable Palm Oil): ISPO is a mandatory certification for Indonesian palm oil producers. It was created by the Indonesian government to ensure sustainable practices that align with national laws and regulations. ISPO’s standards focus on reducing environmental impacts, maintaining biodiversity, and improving the welfare of local communities. By adhering to ISPO, companies demonstrate their commitment to environmentally sound and socially responsible practices, although the certification is largely focused on Indonesia’s specific requirements.

2. MSPO (Malaysian Sustainable Palm Oil): Similarly, MSPO is Malaysia’s national standard for sustainable palm oil production. Like ISPO, it is tailored to the specific needs and regulations of Malaysia. MSPO certification aims to improve traceability, reduce environmental damage, and ensure fair labor practices within the palm oil industry. As a government-backed initiative, MSPO has helped Malaysia boost its image as a responsible palm oil producer and aligns with the country’s sustainability goals.

In addition to certifications like RSPO, ISPO, and MSPO, there is growing interest in measuring the carbon footprint and other sustainability metrics of palm oil production. These metrics allow companies to quantify their environmental impact and identify areas for improvement. By tracking metrics such as greenhouse gas emissions, energy consumption, and water use, companies can set goals to reduce their carbon footprint over time.

Sustainability metrics also play a crucial role in corporate social responsibility (CSR) initiatives. Many companies today are committed to reducing their carbon emissions and improving their environmental practices to meet the expectations of consumers and shareholders. By tracking and reporting on sustainability metrics, businesses can show their commitment to minimizing their environmental impact, fostering transparency, and encouraging more responsible practices in the industry.

Achieving a sustainable and traceable palm oil supply chain is not just an environmental imperative but also a business necessity. As consumer demand for ethical products grows, stakeholders across the industry must collaborate to implement robust traceability systems, uphold ethical sourcing practices, and invest in sustainable agricultural techniques. By leveraging technology and fostering transparency, the palm oil sector can mitigate its environmental impact while enhancing economic resilience for farmers and communities. Together, we can pave the way for a more sustainable future, ensuring that palm oil production contributes positively to the planet and its people.

Palm oil production has been linked to deforestation, biodiversity loss, and greenhouse gas emissions. However, sustainable practices and certifications are helping to address these issues.

Traceability means tracking the journey of palm oil from the plantation to the end product, ensuring transparency and accountability at each stage.

Technology like blockchain, satellite monitoring, and IoT devices can help monitor and optimize the supply chain, making it more sustainable and compliant with global standards.