Contact: +91 99725 24322 |

Menu

Menu

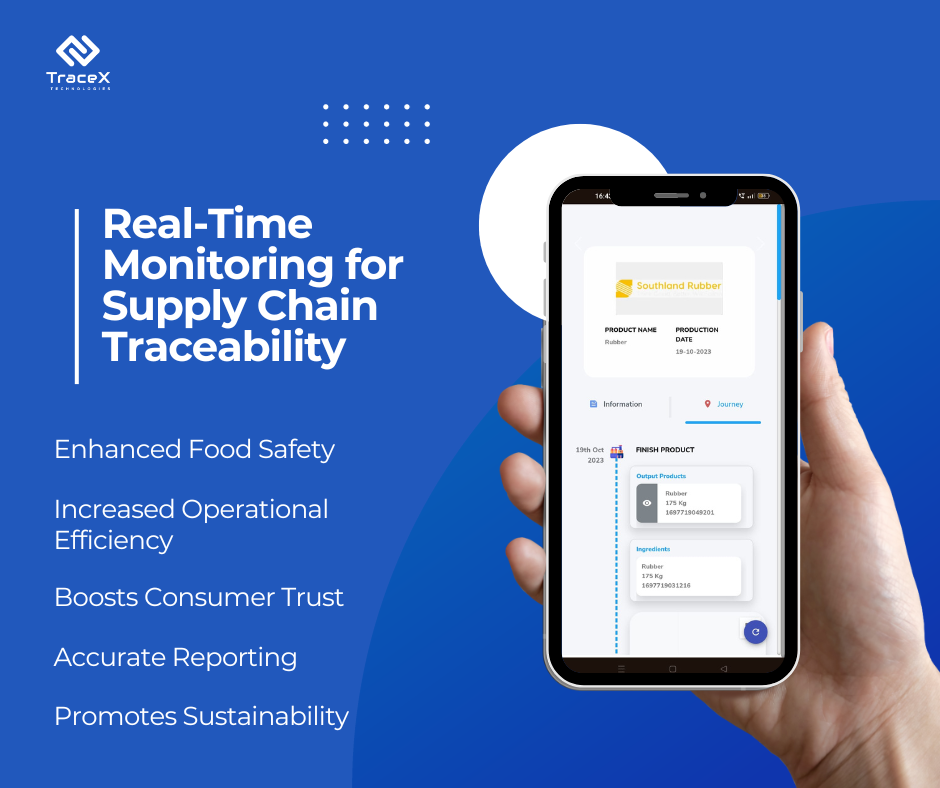

Quick summary: Explore how real-time monitoring boosts supply chain visibility. Discover how technologies like IoT, blockchain, and dynamic QR codes enhance transparency, reduce risks, and improve operational efficiency in supply chain management.

Do you know that supply chain disruptions can cost businesses millions and erode customer trust overnight. Imagine having a shipment delayed due to unforeseen bottlenecks or losing track of inventory at a critical point in production—these challenges can cripple operations. Real-time monitoring offers a powerful solution by providing instant insights and end-to-end visibility into every stage of the supply chain.

50%+ of companies lack end-to-end supply chain visibility driving them to add oversight to mitigate disruption risk.

With this transparency, businesses can proactively manage risks, respond to disruptions, and make data-driven decisions to keep the supply chain running smoothly. But how do companies harness this capability effectively? Let’s dive in.

Key Takeaways

Real-time monitoring in supply chain management involves the continuous, instantaneous tracking and analysis of data throughout the entire supply chain. Unlike traditional monitoring, which often relies on periodic updates, real-time monitoring provides up-to-the-minute information on inventory levels, production processes, and shipment status. This approach utilizes advanced technologies like IoT sensors, RFID, and data analytics to deliver immediate insights. The key difference lies in the speed of data acquisition and the agility it offers in responding to changes promptly. Real-time monitoring empowers businesses to proactively manage potential issues, optimize workflows, and enhance overall supply chain traceability, ultimately improving responsiveness and adaptability.

At the core of any effective supply chain is visibility. Businesses that have limited or no visibility into their supply chain are often left in the dark about potential inefficiencies, risks, or disruptions. Real-time monitoring changes that dynamic by providing a live view of the entire supply chain in motion, making it easier for businesses to manage and optimize their operations.

Here’s why real-time monitoring is critical for supply chain visibility:

Achieving real-time visibility requires the right set of technologies. Several tools and systems are used to collect, analyze, and share real-time data across the supply chain. Some of the most popular technologies include:

A Spice Tech company transformed its online platform from limited visibility to a secure, transparent marketplace using TraceX blockchain traceability solutions. This shift empowered farmers and ensured verified data throughout the supply chain, fostering trust and promoting a more sustainable and ethical spice industry.

Organic India streamlined its agricultural operations and digitized farm management with TraceX’s solutions. The platform enabled tracking of regenerative practices, optimized procurement, ensured product traceability, and validated quality certifications, enhancing efficiency and transparency across their supply chain.

Problem: In the agricultural supply chain, ensuring fair transactions and transparent traceability are essential for building trust between farmers and buyers, improving operational efficiency, and promoting sustainable agricultural practices.

Real-Time Solution: Bluetooth-enabled weighing scales helps streamline the weighing process at procurement points. These scales automatically capture the weight of the produce and send the data in real-time to the central system. After the produce is weighed, dynamic QR codes are generated and affixed to each batch of goods. These QR codes are linked to the product’s real-time data, including weight, origin, date of procurement, and additional product-specific information such as quality parameters.

Benefit: The real-time data ensures that farmers receive accurate compensation based on the actual weight, minimizing errors that might occur with manual methods. As the produce moves from the farm to processing, warehousing, and distribution centers, the QR code updates with real-time data on each stage of the journey. This enables continuous tracking and traceability of the produce, ensuring full transparency.

1. Cost Reduction

Real-time monitoring helps businesses minimize operational costs by identifying inefficiencies and bottlenecks early. By optimizing inventory management and reducing waste, companies can reduce storage costs, transportation expenses, and potential losses caused by delays or damaged goods.

2. Improved Customer Experience

Transparency and real-time updates are key to improving customer satisfaction. With the ability to track their orders and receive accurate delivery timelines, customers can plan better and have a more seamless experience. Real-time monitoring also allows businesses to provide proactive communication in case of delays, further enhancing trust and loyalty.

3. Enhanced Collaboration

Real-time data fosters collaboration across all stakeholders in the supply chain. Suppliers, manufacturers, logistics providers, and distributors can access the same data, enabling them to coordinate more effectively and resolve issues collaboratively. This improved communication leads to smoother operations and fewer misunderstandings.

4. Regulatory Compliance

Real-time monitoring ensures that businesses can comply with various industry regulations, such as food safety standards or environmental sustainability requirements. By tracking the conditions in which goods are stored and transported (e.g., temperature for food products), businesses can ensure compliance with regulatory guidelines and avoid costly fines. In the complex regulatory landscape, due diligence is more crucial than ever, especially in industries like agribusiness, food production, and supply chain management. Real-time monitoring plays a pivotal role in ensuring that businesses comply with regulatory requirements, avoid risks, and maintain transparency throughout their operations

5. Scalability

As your business grows, your supply chain becomes more complex. Real-time monitoring tools can scale with your operations, providing you with the necessary insights and data to manage your supply chain more efficiently, even as you expand into new markets or increase your product offerings.

1. Define Your Objectives

Before implementing a real-time monitoring system, it’s essential to define your goals. Are you looking to improve delivery times, enhance transparency, reduce costs, or increase operational efficiency? Identifying your objectives will help you choose the right tools and set measurable KPIs to track your success.

2. Choose the Right Technology

Based on your supply chain needs, select the appropriate technologies for monitoring. This could involve implementing IoT sensors, GPS tracking, or a cloud-based supply chain management platform. Make sure the chosen solutions integrate seamlessly with your existing systems to ensure smooth data flow.

3. Ensure Data Integration

For real-time monitoring to be effective, data from various sources (e.g., suppliers, warehouses, transportation) needs to be integrated into a centralized platform. This allows all stakeholders to access the same data and make informed decisions based on a unified view of the supply chain.

4. Train Your Team

Implementing new technologies requires that your team is well-versed in how to use them. Provide training to your supply chain managers, IT staff, and relevant stakeholders to ensure that they are comfortable using real-time monitoring tools and can leverage them to make informed decisions.

5. Monitor and Optimize

After implementing real-time monitoring, continuously monitor the system’s performance. Regularly assess your KPIs, gather feedback from stakeholders, and identify areas where improvements can be made. Use the data collected to optimize your supply chain processes and drive continuous improvement.

TraceX’s Food Traceability Platform empowers food businesses with the tools they need to ensure transparency, food safety, operational efficiency, and compliance. By leveraging blockchain technology and real-time monitoring, TraceX enables businesses to build stronger relationships with consumers, stakeholders, and partners while fostering a sustainable and trustworthy food supply chain.

In today’s rapidly evolving business environment, real-time monitoring is a game changer for enhancing supply chain visibility. By leveraging advanced technologies like IoT sensors, blockchain, and dynamic QR codes, companies can continuously track the movement of goods, ensure compliance, improve operational efficiency, and make informed decisions. With real-time access to data, businesses can proactively address issues, improve transparency, and build stronger relationships with stakeholders. As supply chains become more complex, real-time monitoring will continue to play a pivotal role in driving sustainability, reducing risks, and fostering a competitive edge in the market.

Real-time monitoring refers to the use of advanced technologies such as IoT, blockchain, and GPS to track goods and processes throughout the supply chain as they occur. It ensures continuous visibility, allowing businesses to identify issues instantly and improve decision-making.

By providing continuous access to up-to-date data, real-time monitoring enhances transparency in the supply chain. Technologies like dynamic QR codes and blockchain create an immutable record of transactions, ensuring stakeholders can track the origin, movement, and condition of products throughout their journey.

The benefits include improved risk management, enhanced regulatory compliance, optimized operations, and increased customer trust. It helps businesses proactively address issues such as delays, fraud, or non-compliance, while driving cost savings and operational efficiency.