Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Discover how real-time supply chain visibility powers transparency and compliance with EUDR, ESG, and global trade regulations. Learn benefits, use cases, and FAQs.

Global supply chains are under more scrutiny than ever. From regulations like the EU Deforestation Regulation (EUDR) and ESG reporting requirements, to rising customer expectations and constant disruption risks, businesses can no longer afford blind spots in their operations. Real-time supply chain visibility means continuously tracking goods, data, and processes across every tier of the supply chain, from raw material origin to final delivery.

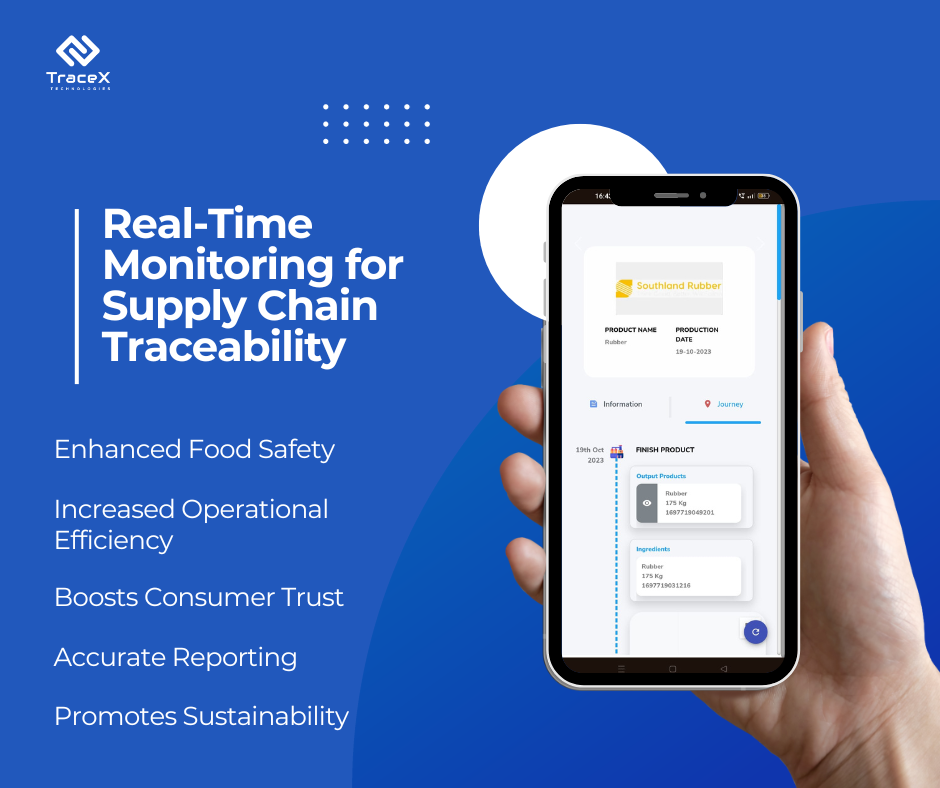

Real-Time Supply Chain Visibility powers transparency and compliance by providing continuous, end-to-end tracking of products, suppliers, and geolocations. Instead of relying on fragmented reports or delayed updates, businesses gain live insights into sourcing, logistics, and certifications. This ensures traceability for regulations like EUDR, accurate risk assessments, and tamper-proof audit records. For exporters and importers, real-time visibility reduces blind spots, prevents compliance gaps, and builds trust with buyers and regulators. By linking every shipment to verified data in real time, companies move from reactive compliance to proactive, transparent supply chain management.

In this blog, we’ll show how real-time visibility powers transparency and compliance—helping businesses meet strict regulatory standards, reduce audit risks, and build trust with buyers through accurate, live supply chain data.

Key Takeaways

Real-time supply chain visibility means the continuous tracking of products, shipments, and supplier data across every tier of the supply chain. It provides businesses with live, accurate insights into the movement and compliance status of goods—from raw material origins to customer delivery.

Because without it, companies face blind spots that create risks—missed regulatory deadlines (like EUDR DDS filings), delays, and loss of buyer trust. Real-time visibility allows businesses to move from reactive problem-solving to proactive risk management.

Regulators are raising the bar with frameworks like the EU Deforestation Regulation (EUDR), the US Uyghur Forced Labor Prevention Act (UFLPA), and expanding ESG disclosure rules. Real-time visibility reduces compliance risk by linking geolocation data, supplier certifications, and batch-level tracking directly to shipments. Instead of scrambling for documents during audits, companies can generate proof of deforestation-free and ethically sourced goods instantly, making regulatory inspections smoother and lowering the risk of fines or market bans.

Most companies still rely on static spreadsheets and disconnected systems to manage supplier and shipment data. This leads to blind spots, duplication, and costly manual errors. Real-time visibility replaces this with dynamic dashboards that consolidate supplier onboarding, shipment status, and compliance records in one place. Teams gain live updates on SKUs, DDS filings, and certifications, which cuts down processing time, reduces rework, and ensures audit readiness at scale.

Trust across global supply chains is often fragile, especially when exporters, importers, and farmers operate in silos. Real-time visibility bridges this gap by creating a shared, tamper-proof view of the supply chain. Exporters can demonstrate transparent sourcing practices, importers can validate DDS compliance, and farmers gain recognition for sustainable practices. This not only strengthens buyer confidence but also improves long-term supplier relationships, enabling better contract terms and preferred partnerships.

Compliance starts with visibility.

Discover

How supply chain visibility drives compliance

How digital traceability simplifies EUDR

in our latest blogs.

Think of your supply chain like a live map. If you only update that map once a month with spreadsheets and PDFs, you’re basically navigating blindfolded reacting after the fact instead of staying ahead. And in 2025, blindfolds aren’t an option.

Take EUDR, for example. Importers need to prove that every shipment is deforestation-free, with geolocation data tied back to the exact farm plot. It’s not enough to collect this once and hope it sticks—EU TRACES requires live, verifiable information that regulators can cross-check at any moment. The same goes for ESG reporting frameworks: stakeholders aren’t just asking for “what you did last year,” they’re demanding ongoing proof that your sourcing and operations are responsible right now.

And here’s the kicker—this isn’t just about avoiding fines or rejected shipments. Real-time supply chain visibility actually builds trust with buyers and consumers. Imagine being able to show a chocolate manufacturer in Belgium, or a retailer in Germany, the exact satellite coordinates of the farm where the cocoa was grown—in seconds. That turns compliance data into a business advantage.

When you move from static reports to dynamic dashboards, you’re no longer scrambling at the last minute to piece together supplier documents. Instead, you can spot risks before they escalate, course-correct in real time, and walk into audits with confidence.

Transparency and compliance aren’t separate goals—they’re two sides of the same coin, and real-time data is the currency.

If you’ve ever tried to juggle supplier spreadsheets, WhatsApp updates from the field, and last-minute compliance requests from buyers—you know the chaos. Real-time supply chain visibility platforms are built to turn that chaos into clarity. Here’s how:

Instead of chasing farmers, exporters, and brokers for siloed data, imagine one shared system where supplier profiles, certifications, and GeoJSON farm coordinates live together. For EUDR compliance, that means you can trace a container of cocoa back to the exact plot in Ivory Coast without opening 20 different files.

Think of every transaction, from harvest to shipment, locked into a digital ledger that can’t be altered. IoT sensors feed real-time updates—like temperature for cold storage or truck GPS routes—while blockchain ensures nobody can fudge the numbers later. The result? A compliance record that auditors (and your buyers) actually trust.

Instead of waiting for an NGO report or regulator letter to flag risks, AI scans supplier data, satellite images, and country benchmarks as it happens. That means you can get an alert if, say, deforestation is detected near a sourcing area in Brazil, giving you time to pivot before it becomes a compliance disaster.

Let’s be honest: filing Due Diligence Statements (DDS) or ESG reports manually is a nightmare. Automated platforms turn that data you’re already collecting into ready-to-submit formats for EU TRACES or sustainability disclosures. What used to take days of manual collation now takes minutes—without the human error.

The bigger story? These platforms don’t just help you tick regulatory boxes. They free up your team from firefighting, strengthen buyer trust with verifiable data, and position your brand as a leader in transparent, sustainable trade.

A Spice Tech company transformed its online platform from limited visibility to a secure, transparent marketplace using TraceX blockchain traceability solutions. This shift empowered farmers and ensured verified data throughout the supply chain, fostering trust and promoting a more sustainable and ethical spice industry.

Organic India streamlined its agricultural operations and digitized farm management with TraceX’s solutions. The platform enabled tracking of regenerative practices, optimized procurement, ensured product traceability, and validated quality certifications, enhancing efficiency and transparency across their supply chain.

Problem: In the agricultural supply chain, ensuring fair transactions and transparent traceability are essential for building trust between farmers and buyers, improving operational efficiency, and promoting sustainable agricultural practices.

Real-Time Solution: Bluetooth-enabled weighing scales helps streamline the weighing process at procurement points. These scales automatically capture the weight of the produce and send the data in real-time to the central system. After the produce is weighed, dynamic QR codes are generated and affixed to each batch of goods. These QR codes are linked to the product’s real-time data, including weight, origin, date of procurement, and additional product-specific information such as quality parameters.

Benefit: The real-time data ensures that farmers receive accurate compensation based on the actual weight, minimizing errors that might occur with manual methods. As the produce moves from the farm to processing, warehousing, and distribution centers, the QR code updates with real-time data on each stage of the journey. This enables continuous tracking and traceability of the produce, ensuring full transparency.

TraceX combines the intelligence of AI with the security of blockchain. AI continuously scans supplier data, satellite imagery, and risk benchmarks to flag potential compliance issues before they become liabilities. Meanwhile, blockchain locks every transaction—from harvest records to shipment details—into an auditable ledger that can’t be tampered with. That’s peace of mind for exporters and ironclad proof for buyers.

Every farm plot in your supply chain is digitally mapped through GeoJSON coordinates. TraceX links these maps with deforestation databases, country risk profiles, and supplier details to give you an automated risk score. Instead of guesswork, you know exactly which regions and suppliers are low, medium, or high risk—empowering smarter sourcing decisions.

The biggest headache for importers and exporters under EUDR is filing Due Diligence Statements (DDS). TraceX automates the heavy lifting. Once supplier data and geolocation are captured, you can generate and submit DDS directly into the EU TRACES system with a single click. No more manual cut-and-paste across systems.

From the moment a farmer harvests cocoa, coffee, or timber, TraceX captures every step of the journey—storage, processing, export, import. By the time the goods reach the EU, you have a continuous, tamper-proof digital record that connects farm to customs. It’s transparency your buyers can see, and compliance regulators can trust.

Real-time supply chain visibility isn’t just a compliance checkbox — it’s a business advantage. By digitizing supplier data, mapping origins, and integrating compliance into daily workflows, companies gain resilience, buyer trust, and smoother market access. Whether you’re preparing for EUDR, ESG audits, or future regulations, the companies that embrace visibility today will be tomorrow’s leaders in transparency and sustainability.

Get practical insights on how to strengthen your compliance journey.

Because it ensures every shipment, supplier, and location is continuously tracked, helping companies avoid fines, customs delays, and reputational risks.

It links products to geolocation data, verifies supplier compliance, and generates Due Diligence Statements (DDS) for EU TRACES quickly and accurately.

Agriculture, food, timber, rubber, leather, and other EUDR-listed commodity sectors, as well as businesses preparing for ESG audits and sustainability reporting.