Contact: +91 99725 24322 |

Menu

Menu

Quick summary: Unlock the power of supply chain visibility across tiers with our comprehensive guide. Discover strategies, tools, and best practices to enhance collaboration, mitigate risks, and optimize operations for greater efficiency and resilience.

In today’s complex global marketplace, supply chains extend across multiple tiers, involving numerous suppliers, manufacturers, distributors, and retailers. This intricate network presents both challenges and opportunities for businesses. Achieving supply chain visibility across tiers is essential for optimizing operations, enhancing efficiency, and mitigating risks.

According to a survey conducted by Deloitte on Chief Procurement Officers (CPOs), just 15% of them reported having visibility beyond their tier-one suppliers. Gaining visibility into tier-one suppliers alone is already a significant challenge.

Supply chain visibility refers to the ability of organizations to track and monitor the movement of goods, information, and resources across various stages of the supply chain in real-time or near real-time. It involves gaining insights into inventory levels, production processes, transportation activities, and other relevant data points to facilitate informed decision-making and enhance operational efficiency.

Visibility in supply chain management is essential for several reasons. Firstly, it enables organizations to identify potential bottlenecks, delays, and inefficiencies within their supply chains, allowing them to proactively address issues and minimize disruptions. Additionally, enhanced visibility enables better demand forecasting, inventory management, and resource allocation, leading to cost savings and improved customer satisfaction. Moreover, in an increasingly complex regulatory environment, visibility helps organizations ensure compliance with various industry standards and regulations.

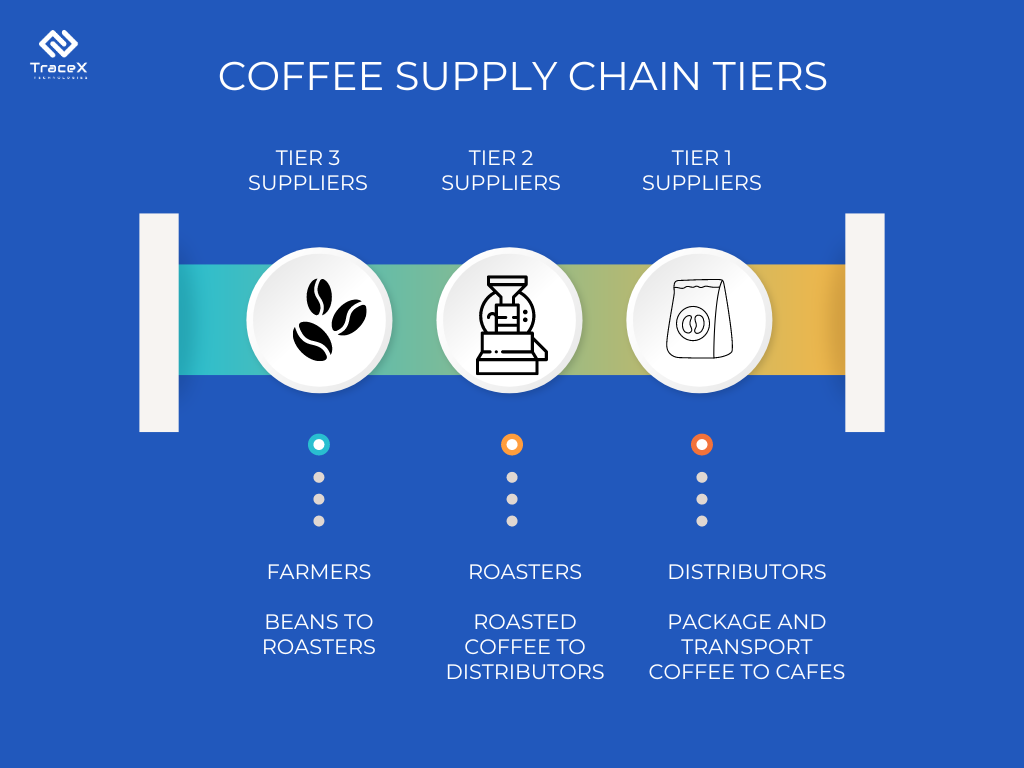

Supply chains are typically divided into multiple tiers, each representing different stages of production, distribution, and procurement. Understanding and managing these supply chain tiers is critical for organizations to gain comprehensive visibility into their operations. Tier-one suppliers directly supply goods or services to the focal organization, while tier-two and subsequent tiers consist of suppliers further upstream in the supply chain. Each tier plays a vital role in the overall supply chain network, and visibility across these tiers enables organizations to identify dependencies, assess risks, and optimize performance effectively.

Supply chain tiers are often categorized based on the proximity of suppliers to the focal organization. Tier 1 suppliers are those directly engaged with the focal organization, providing essential goods or services for production or distribution. Tier 2 suppliers are upstream from Tier 1, supplying components or raw materials to Tier 1 suppliers. Subsequent tiers continue this chain, with Tier 3, Tier 4, and so forth representing suppliers further upstream in the supply chain network.

Each supply chain tier fulfills specific roles and functions that contribute to the overall efficiency and effectiveness of the supply chain. Tier 1 suppliers typically have direct relationships with the focal organization, supplying critical components or finished products. Tier 2 and subsequent tiers provide the necessary inputs and resources for Tier 1 suppliers, enabling the production process to proceed smoothly. Additionally, each tier may have its own set of suppliers, subcontractors, and logistics partners, further diversifying the supply chain network.

A significant challenge in supply chain management is the lack of visibility across different tiers. Limited visibility makes it difficult for organizations to track the movement of goods, assess supplier performance, and identify potential risks or disruptions. Without visibility across supply chain tiers, organizations may encounter issues such as delays, quality issues, and inventory imbalances, leading to increased costs and customer dissatisfaction. Additionally, compliance with regulations and standards becomes more challenging without comprehensive visibility, exposing organizations to regulatory risks and liabilities. Overcoming these challenges requires implementing robust supply chain visibility solutions and fostering collaboration across supply chain tiers to enhance transparency and coordination.

Visibility across supply chain tiers offers numerous advantages for organizations seeking to optimize their operations, mitigate risks, and enhance collaboration with partners.

Visibility across supply chain tiers enables organizations to gain real-time insights into inventory levels, movement, and demand patterns. With enhanced visibility, organizations can accurately track inventory across multiple tiers, reducing the risk of stockouts or overstocking. Additionally, access to timely data allows for more accurate demand forecasting, helping organizations align production schedules and inventory levels with customer demand. By optimizing inventory management and demand forecasting, organizations can minimize carrying costs, improve order fulfilment rates, and enhance customer satisfaction.

Visibility across supply chain tiers facilitates proactive risk management and enhances organizational resilience in the face of disruptions. By monitoring supplier performance, production processes, and transportation networks across multiple tiers, organizations can identify potential risks and vulnerabilities early on. This enables proactive risk mitigation strategies, such as diversifying supplier networks, securing alternative transportation routes, and building buffer inventory to buffer against supply chain disruptions. Additionally, enhanced visibility enables organizations to quickly respond to unforeseen events, such as natural disasters, geopolitical tensions, or supplier failures, minimizing the impact on operations and ensuring business continuity.

Visibility across supply chain tiers fosters transparent communication and collaboration among supply chain partners, driving operational efficiency and effectiveness. By sharing real-time data and insights with suppliers, manufacturers, distributors, and other stakeholders, organizations can streamline processes, optimize resource allocation, and synchronize production schedules. Enhanced collaboration enables proactive problem-solving, facilitates joint decision-making, and strengthens relationships with supply chain partners. Additionally, improved communication fosters trust and transparency across the supply chain network, laying the foundation for long-term partnerships and mutual success.

Visibility across supply chain tiers is essential for optimizing operations and ensuring resilience in today’s complex business environment.

Initiate the process by mapping out your Tier 1 suppliers, categorizing them based on their criticality to your business. This initial step provides a foundation for further analysis. Develop a comprehensive overview of supplier tiers for key suppliers to bolster risk management and pinpoint areas for improvement.

2. Implement a Traceability System

Introduce a robust traceability system to track the journey of products and materials across the supply chain. This system facilitates a clear understanding of the composition of end products and ensures compliance with essential requirements.

3. Cultivate Transparent Communication

Establish formal and informal channels for communication and governance across all levels of the supply chain. Transparent sharing of material origin and sourcing details fosters trust among stakeholders.

Implementing a traceability system is vital for effective supplier tier management within the supply chain. By introducing a robust traceability system, companies can gain insights into the journey of products and materials across various tiers of suppliers. This system enables clear visibility into the composition of end products, allowing businesses to trace back the origin of each component to its respective supplier.

Companies can use traceability data to identify and map out their supplier relationships across different tiers. This allows for a comprehensive understanding of the supplier landscape and the dependencies between different tiers.

With a traceability system in place, businesses can better manage risks associated with their suppliers. They can track the origin of materials and identify potential vulnerabilities or disruptions within the supply chain, particularly at lower tiers where risks may be less visible.

Traceability systems facilitate compliance with regulatory requirements and industry standards by ensuring transparency and accountability in the supply chain. Companies can track the flow of materials and verify that suppliers adhere to specific regulations and quality standards.

By tracking the journey of products and materials, companies can monitor the quality and integrity of components sourced from different tiers of suppliers. This allows for early detection of any deviations or issues that may affect product quality.

Traceability data provides valuable insights into supplier performance across various tiers. Companies can analyze supplier data to assess performance metrics such as delivery times, product quality, and compliance with contractual obligations.

As we delve deeper into the supply chain tiers, visibility becomes increasingly obscured. Manual tracking of such extensive data is impractical. Therefore, automating data collection and analysis is imperative.

Critical Supplier Key Performance Indicators (KPIs) encompass supplier inventory, lead times, quality, delivery performance, sustainability, and diversity. Challenges in maintaining service levels may indicate underlying issues further along the chain.

TraceX’s Supply chain management software solutions are simplifying the process of mapping tier 2 and 3 suppliers and monitoring supplier performance across all tiers. Real-time visibility facilitates prompt responses to significant issues as they arise.

Data-driven solutions from TraceX play a pivotal role in supply chain tier management by offering comprehensive visibility and control across all tiers. Leveraging advanced technologies like blockchain and IoT, TraceX enables real-time tracking of products and materials as they move through different tiers of the supply chain. This visibility allows businesses to map their supplier networks, monitor supplier performance, and identify potential risks or bottlenecks at each tier. By collecting and analysing data on key metrics such as supplier inventory, lead times, quality, and sustainability performance, TraceX empowers organizations to make informed decisions, optimize processes, and ensure compliance with regulatory requirements. Ultimately, these data-driven insights enable businesses to enhance efficiency, mitigate risks, and build more resilient and transparent supply chains.

Explore our TraceX Blockchain Platform

In conclusion, achieving supply chain visibility across tiers is essential for modern businesses to thrive in today’s complex global marketplace. By implementing strategies such as mapping supplier networks, establishing traceability systems, fostering open communication, and leveraging data-driven solutions, organizations can overcome the challenges associated with supply chain complexity. With enhanced visibility, businesses can effectively manage risks, improve collaboration with suppliers, optimize inventory management, and ultimately deliver greater value to customers. As technology continues to evolve and supply chains become increasingly interconnected, prioritizing visibility across tiers will remain a critical imperative for driving innovation, resilience, and sustainability in supply chain management.